Technical Cleanliness – Clean Rooms in Every Classification

Particulate contamination is a challenge in almost any production environment. The more sensitive the processes and products are, the higher the cleanliness requirements. The ASYS Group has many years of know-how and sophisticated solutions in the fields of technical cleanliness and clean room technology.

A first and important step in particle reduction is usually to find out which particles, in which size, are critical for the respective process. Particle size and density in particular influence the possible measures that are available to control the particles and their formation and spread. For the analysis of particles different methods are available, depending on the type of particles (airborne / non-airborne).

Analysis of Airborne Particles

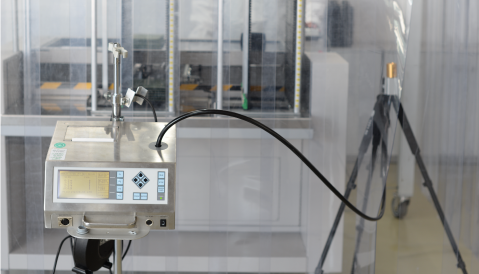

Starting with airborne particles – here we are moving in the field of clean room technology – we offer particle measurements to solve the most different problems together with you. In addition to the qualification of clean rooms or laminar flow units, process machines can also be tested for their clean room suitability.

For this purpose we use our LAMINO Cabin, in which a clean room class up to ISO 5 can be achieved, and a particle measuring device with which the size and number of particles over a defined period of time and/or a defined air volume can be determined. The measurements can be used to answer the questions of what effect the process machine has on the surrounding clean room, as well as which clean room class can be realized within the process machine.

Analysis of non-airborne particles

For the analysis of non-airborne particles, so-called particle traps are used. With the help of these traps, all particles that are generated above the product area and fall down are collected over a defined period of time. Afterwards the particles are analyzed and divided into different categories (e.g. metallic, non-metallic; shiny, non-shiny).

Together with you, we determine in which areas of the process critical particles arise and define measures and solutions to eliminate them.

Benefits

- Competent advice and implementation thanks to years of experience

- Qualified processes & plants regarding cleanliness

- Adapted to your needs

- Optimization of the manufacturing processes

You have particle-sensitive processes and are looking for a suitable partner for questions in the areas of cleanroom technology and technical cleanliness? We would be pleased to support you in finding optimal solutions for your processes.

Contact Person

Florian Buchfink

Technical Sales Manager

florian.buchfink(at)asys-group.com