Handling Trends In Focus

Handling Trends In Focus

ASYS has changed the product management in a sustainable way and created a new level of responsibility. The product management is now divided into the areas "Product Management" (PM) and "Product Line Management" (PLM). This new structure makes it possible to accelerate processes, increase quality and create consistent transparency. In the product area VEGO Handling, Markus Glaß and Jürgen Lehner form a strong team to implement your handling topics at the highest level.

Jürgen Lehner

"I can now devote more time to product portfolio strategy, new and further development as well as support for marketing and sales, while Markus supports me with order processing and second level support. The division of tasks allows us to focus more intensively on individual topics."

Markus Glaß

"Mein Fokus liegt derzeit auf der Optimierung unserer internen Fertigungsabläufe. Mein Ziel ist es, unsere Anlagen mit gleichbleibend hoher Qualität und möglichst Null-Fehler auszuliefern. Dazu gehört auch die Einhaltung der termingerechten Lieferung."

In a discussion on the current challenges in the field of handling, the duo will provide exciting insights and outlooks on solutions that make a decisive contribution to automated processes in the intelligent factory.

What challenges do you currently see in the handling area?

Lehner: The challenge in our area, which is, in fact, transferable to the entire production environment, is the increased autonomy requirement for processes. We need solutions that work intelligently, error-free and automated.

Glaß: Cost savings and output increase, these are the classic drivers. However, we still incorporate important aspects such as traceability or autonomous material supply into our product developments. This is the only way we can tackle current and future challenges.

How do you approach the challenges?

Lehner: It is important to approach the matter with foresight. Therefore we observe trends closely and spin ideas in ASYS-manner, which can go in any direction.

Glaß: Close cooperation with our customers on development issues is extremely important to us. They know their challenges best. We then combine our know-how with their needs and create individual solutions.

What concrete solutions do you offer in the product area Handling?

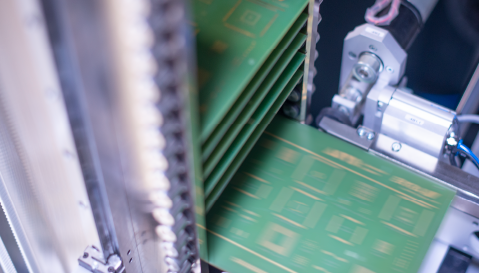

Glaß: With our proven loaders and unloaders AES03D and AMS03D, we will show how up to three assemblies can be stored within one magazine slot by integrating a newly developed pusher and extractor with position measuring system. The printed circuit boards do not touch each other at any time, neither during loading nor during unloading. Our unique magazine solution with patented clamping technology ensures that this remains the case even during transport of the magazine.

Lehner: In addition, we have now also developed an autonomous solution for raw PCB loading. Until now, PCB stacks were delivered to the line in boxes and then had to be fed manually to the stack loader. With the AES 03Speed line loader, we can separate PCBs from the stack or remove them from a magazine and feed them into the line. The material exchange is done autonomously by robots (AIV).

What further steps will be taken?

Lehner: Throughout the ASYS Group, and this includes the handling sector, we are gradually converting the product portfolio to "smart". We are working intensively on a completely new handling product series. New, smart functionalities, intelligence down to the smallest machine detail - this is our ambitious goal. Only with smart machines does the factory become truly intelligent.

Thank you!

Highlights

Contactless Multiple Loading of Magazine Slots

With the new magazine solution we achieve up to six times more capacity. Thanks to new patented clamping technology, the assemblies can be stored within one slot without touching each other. With the new solution, it is possible to occupy the slots with up to three PCBs behind each other and two rows next to each other, depending on length and width. The PCBs do not touch each other during loading and unloading. The magazine capacity can thus be increased up to sixfold - without compromising on quality. This means fewer magazine changes and thus a resource-saving handling of line loading/unloading. This option is now available for the AES/AMS 03Speed and AES/AMS 03D line types. The assemblies can be loaded/unloaded either one after the other or simultaneously.

- Throughput increase >150% with three PCBs per slot

- Conserving resources and saving space

- Stress-free, contactless handling

Combined Magazine and Stack Loader with Autonomous Loading via AIV

We have extended the functionality of the line loader AES 03Speed so that it can remove assemblies from magazine locations as well as bare PCBs from the stack and feed them into the line. The raw PCBs are transported as a stack within the magazine with AIV and automatically fed into the system. The AES 03Speed is equipped with an additional extra extractor with vacuum gripper. With this vacuum gripper raw PCBs can be separated from the magazine from top to bottom and fed to the production line. During a format change, the gripper automatically adjusts itself in X and Y position so that the PCB is gripped centrally. When changing over to unloading single-sided assemblies from the magazine, the gripper is automatically lifted. The product change can thus be carried out fully automatically. The system combines magazine and stack loader and saves space in the line. In addition, for the first time, PCB stacks can be fed into the line autonomously using AIVs.

- Combined solution for magazines & raw PCB stacks

- Reduced space requirements & lower acquisition costs

- Autonomous processing thanks to AIV connection