Increased Degree of Autonomy for Process Flow – Gradually Extendable!

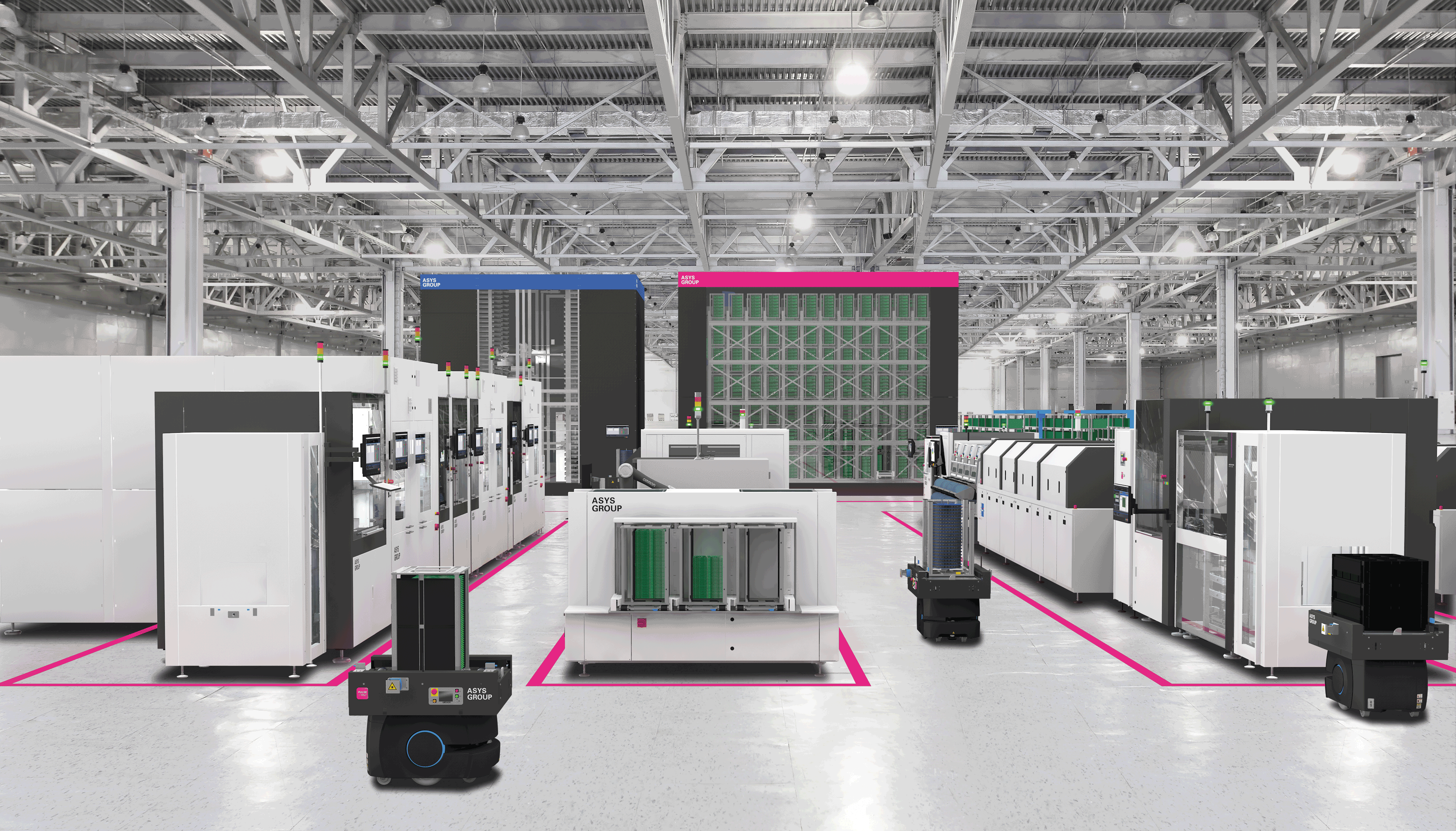

To achieve an increased degree of autonomy for the production lines, material stations were installed as buffer stations for the PCB magazines. In addition, AIVs (Autonomous Intelligent Vehicles) are used for autonomous transport of the magazines. The AIV fleet is coordinated by the software module "Fleetmanager" in the processes, taking into account the charging status and current location of the individual vehicles. Thus, optimized routes are always guaranteed for just-in-time supply according to demand. As a result, the magazines are transported faster and more punctually and the downtimes of the line are reduced. The software module "Logistic-Package" is also used. This provides the networking and connection of all modules for autonomous transport and transfer to the linked machines.

The Software Solutions PULSE and OIC (Overall Inline Communication) are already being used on the existing lines. These modules also provide increased efficiency. Machine messages such as advance warning limits are transmitted to the operator in the right time via smartwatch or tablet. This reduces micro-stops to a minimum. The ASYS Software Solution OIC provides information and evaluations about the production process, which can be used, to analyze and reduce downtimes and to increase the line utilization.

In this project, the possibility was created in advance to test the offered products live in the production. Further steps are the expansion of material logistics with additional connections of Material Stations and AIVs at the lines. A Material Warehouse for central storage of magazines and materials is also being planned. All expansions in the area of MATERIAL LOGISTICS always provide an increased efficiency and represent a further step towards the Smart Factory.

Factors of Decision

Automated production and logistics

The production line and warehouses are supplied with materials by AIVs. This reduces personnel costs and increases process autonomy.

Live Test Scenarios

Previous evaluation by the customer using a live test scenario.

Previous, target-oriented consulting service

Together, we develop individual, scalable concepts to maximize value creation in a long-term perspective. In the process, a modular concept is used, which enables ASYS MATERIAL LOGISTICS solutions to be realized in various degrees of automation.

More about ASYS Material Logistics

More about ASYS Software Solutions