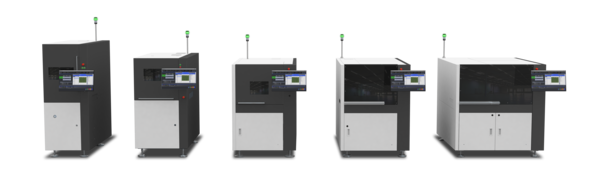

Laser Systems for High-Precision Material Processing

In the POLYPHOS product group, we offer you solutions for material processing using laser technology. Materials such as FR4, polyimide, metal, ceramics, cSi solar cells, etc. can be processed with a variety of laser processes. From laser marking for traceability during the SMT process, processes to increase the efficiency of solar cells, joining processes such as soldering and welding, to micro material processing. Depending on the requirements, the laser system can be individually configured.

We contribute to the transformation from fossil fuels to hydrogen by supplying manufacturing solutions for fuel cells. Our machine solutions are used to manufacture drive components in e-mobility.

Our Highlights:

The Right Laser Process for Every Material

Laser processes are best suited for processing sensitive substrates. They enable the highest precision and reduce mechanical stress to a minimum. Thanks to our technological know-how, we can process almost all kinds of materials using a wide range of laser processes.

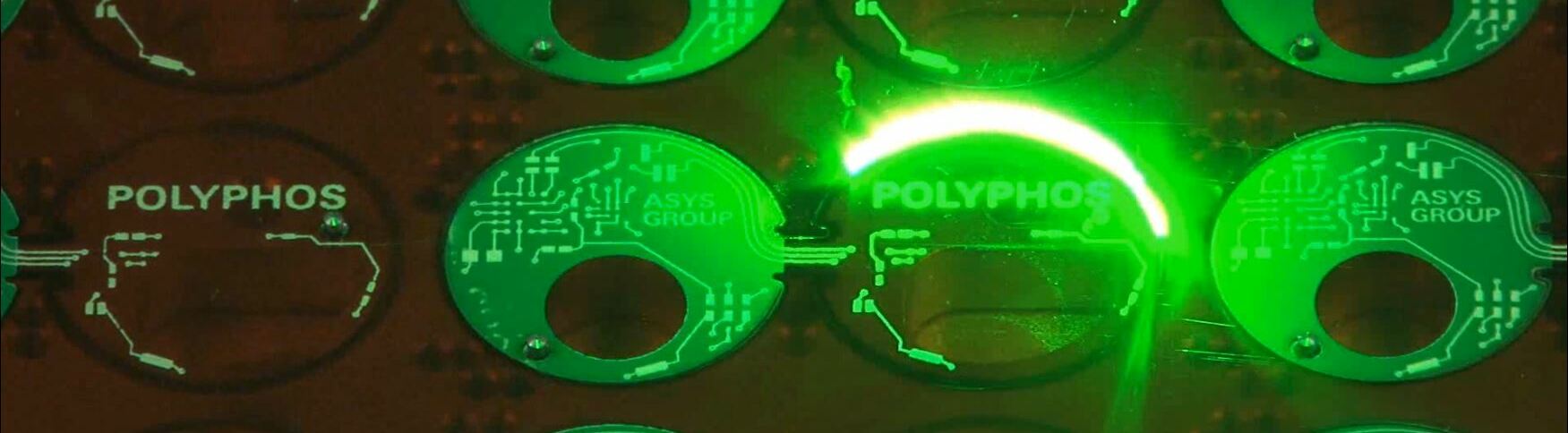

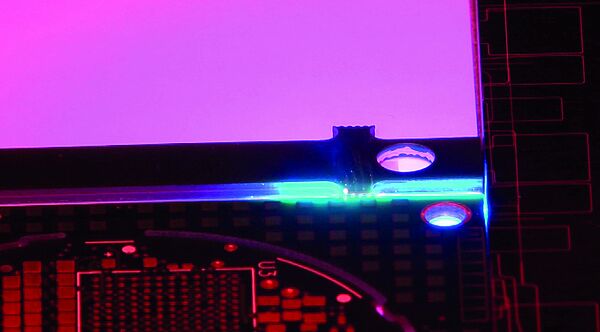

Laser Depaneling

Thanks to the laser, rigid and flexible PCBs can be separated with an accuracy of ±25µm without mechanical stress, as well as particle-free. Our machines meet the requirements for technical cleanliness according to VDA 19 and ISO 16232 and increase the degree of utilization of the PCB panel.

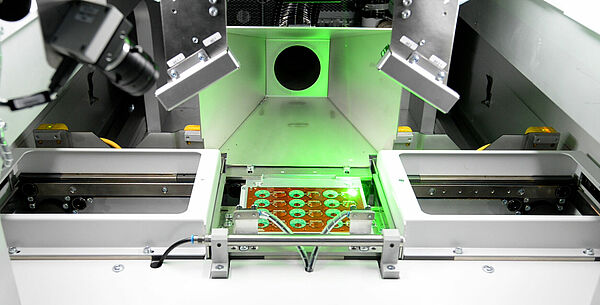

Laser Cutting

Reliable, low-maintenance fiber lasers and precision cutting heads on CNC axes are used for laser cutting of IMS and ceramic substrates. High accuracy is achieved with the help of an on-axis camera and industrial image processing. Gas assist and a particle extraction system ensure technical cleanliness.

Laser Marking

For laser direct marking of electronic (FR4) circuit carriers, CO2 lasers are used for color change and fiber lasers for removing the solder resist. Our product line INSIGNUM stands for the complete traceability solution in the Smart Factory. In addition, we supply individual solutions for metal, plastic and ceramic direct marking, such as UDI marking of ceramic and metal implants using UKP lasers (so-called black marking). Product positioning via 6-axis robots and MOTF (Marking On The Fly) is possible as a customized solution.

Laser Welding

In current developments, we are working on the hermetically sealed welding of automotive camera housings in (partially) autonomous vehicles using CNC welding heads and multi-kW fiber lasers. OCT (Optical Coherence Tomography) is used for process and quality control. In addition, we offer the integration of laser plastic welding processes into our final assembly solutions. A hot topic for us is the laser welding of metallic bipolar plates in fuel cells.

Laser Cleaning

Cleaning surfaces by laser is suitable for tasks where precise, local control is required. This includes surface pretreatment of sealing and bonding surfaces on aluminum die casting, plastic injection molding, and selective removal of flux residues on bond surfaces. Electronics that have already been mounted are not damaged.

Micro Machining

The individual solution for micro material processing, such as scribing, ablation, drilling, etc. of metal, silicon or ceramics. Depending on the process, different automation levels and beam sources are used. For example, we use UKP (ultrashort pulse) lasers for scribing DCB (direct copper bonded) mastercards and for cutting substrates for solid-state batteries to achieve particularly high quality.

Laser Laboratory

In the laboratories at the Dornstadt site, process and application engineers test the latest laser technologies and optimize them for different materials and processes. This enables us to find the right laser process for your product and support you in process qualification.

- In-house laser laboratory

Precision Makes the Difference

We ensure the positioning accuracy of the lasers with a specially developed three-stage calibration procedure and industrial image processing. This ensures the highest precision of our laser processing machines.

- Specially developed calibration procedure

- Guarantees highest precision

Connections to all Systems

With the import/export and synchronization applications of Factory Connect, any data and information are able to communicate with existing MES / ERP systems. Also new standards like an IPC-CFX interface is already integrated in the ASYS PULSE Pro Suite. Here ASYS closes the gap between the shopfloor and superior systems by forming a continuous active data bridge between the shopfloor and the MES of a production.

All ASYS Process Systems - One User Interface

Are you looking for simple and intuitive machine operation? Preferably across all process machines within a line? With SIMPLEX User Interface you control all ASYS systems via a touch display using familiar gestures. This minimizes training times and considerably simplifies operating procedures.

- NEW: SIMPLEX Offline-Tool

With this extension you can create a new product - while production is running.