Depaneling with Precision

Regardless of material, size or contour – our DIVISIO depaneling systems depanel your PCB with an accuracy of ±25μm. Whether as stand-alone solution, inline or offline system – we supply a machine that is perfectly oriented to your requirements and your production. In addition to laser depaneling, we also rely on proven depaneling processes such as sawing and routing. The 1000th sold system speaks for the success and experience in 20 years of DIVISIO depaneling.

Laser Depaneling

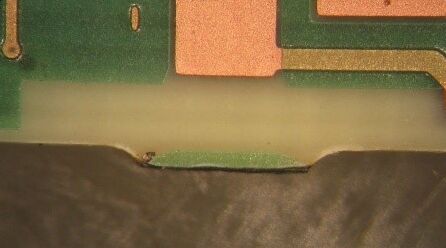

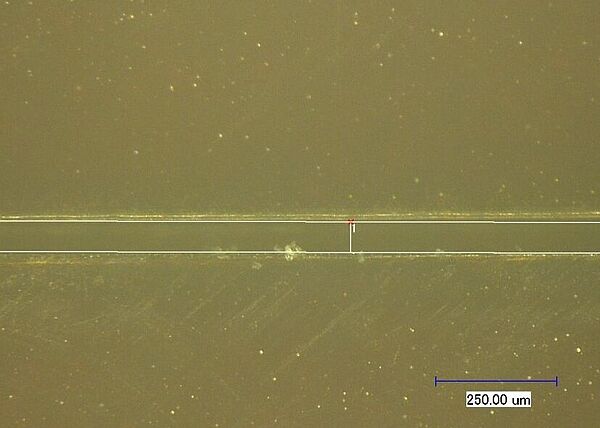

Laser depaneling is a proven depaneling process especially for the life science sector. Thanks to the laser, thin and flexible circuit boards are depanelled with an accuracy of ±25μm. Different types of laser are used. Laser depaneling does not produce dust as with routing or sawing, but only a small amount of suspended matter, which can be effectively extracted. Laser depanelling is a contactless and therefore stress-free process.

Laser processes enable the highest precision and reduce mechanical stress to a minimum. Thanks to our technological know-how from the POLYPHOS product area, we can process almost all conceivable materials using a wide range of laser processes.

Especially with sensitive components, such as circuit boards for pacemakers, you have to rely on sensitive and precise solutions. For this reason, laser depanelling devices are primarily used for pacemakers, defibrillators or similarly sensitive components such as insulin pens or pumps. For many years we have been the supplier of laser depaneling systems for major manufacturers in North America, the United Kingdom and other European countries.

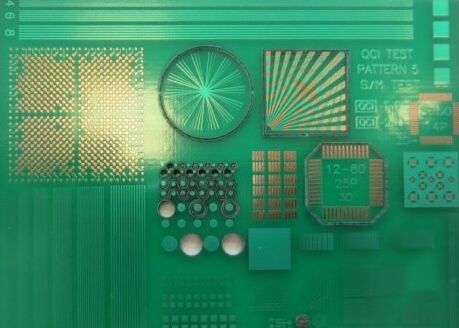

Application tests are often carried out in our own laboratory in advance to find the best balance between laser source and material, with the shortest cycle time in the rrange of milliseconds. Here we offer unique conditions for tests in form of experts and test systems.

You can rely on ASYS – we will find the right solution for you too.

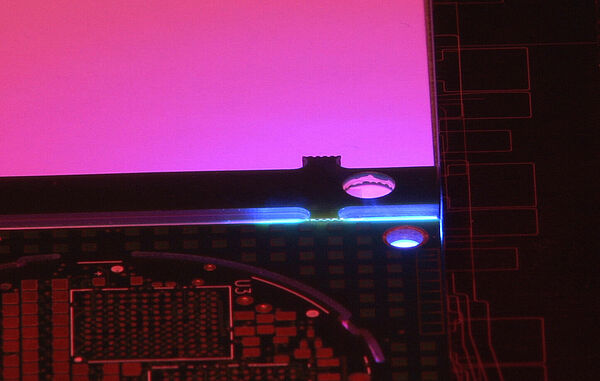

Large-format Flex Panels for Operation Robots

An evaluation of different substrate materials with various properties is often required. So-called flex material (made of polyimide) is often compared with conventional PCB materials such as FR4. The laser source and the power as well as the wavelength are important factors. A test for cutting a large panel of 460 x 305 mm, for example, was excecuted with a POLYPHOS DP 8000 laser.

We are the leading supplier of automation solutions for the electronics industry. In addition, we are supplier for the Life Science industry for many years. Our systems produce medical technology which is used in the diagnosis of many common diseases, such as diabetes.

In order to provide people with diabetes a higher quality of living, sensors are available on the market since several years, which allow a permanent and complete monitoring of the blood glucose level (Continuous Glucose Monitoring / CGM). These sensors are applied subcutaneously (under the skin) every two weeks and remain on the body - even during sports and bathing. A small evaluation device, similar to a smartphone, collects the data wirelessly as required, provides information and shows trends about how much insulin the patient needs and at which time.

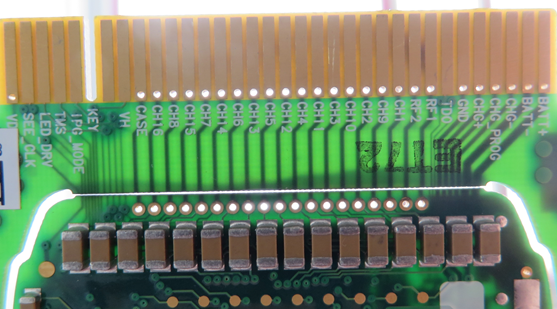

The electronics for the sensor technology for this have been produced on ASYS systems for years. Since a maximum of cleanliness is essential here, the PCBs are cut with laser technology in our DIVISIO 8000 and DIVISIO 9000 laser depaneling machines. This offers high safety and quality and, with cycle times of < 900 milliseconds per individual circuit, is also even faster and gentler for the circuit board of the blood sugar sensor. Also the complete handling, the execution of the function tests and the programming of the circuit is automated on our lines.

Medical Technology Manufacturers and ASYS Practice Simultaneous Engineering

In the meantime, we have installed several systems for this purpose in Europe and the USA, and further systems are currently being planned for the major medical technology manufacturers. As the demand is growing and the technology is developing rapidly, further systems with even smaller and more inconspicuous sensors are under development. They provide even more accurate data and further increase the convenience of the application.

Also in this area, medical technology manufacturers rely on ASYS as their development partner with simultaneous engineering. Because the economical production of the sensor technology and the flawless function through the fully automated process ensures that these solutions can be made available to a large number of patients. Due to the short development cycles of sensor technology and the rapid further development of solutions, reliable partners with know-how in the electronics and GMP area are essential. With our broad portfolio and deep expert know-how, we are perfectly positioned to handle projects with this requirement profile.

This is demonstrated by one of our ongoing projects in the life science sector: at the end of the year, a new product from a major American manufacturer will be launched on the market that will once again set standards and give patients an even better quality of life. We are proud to be able to support this project and to supply the automation for it.