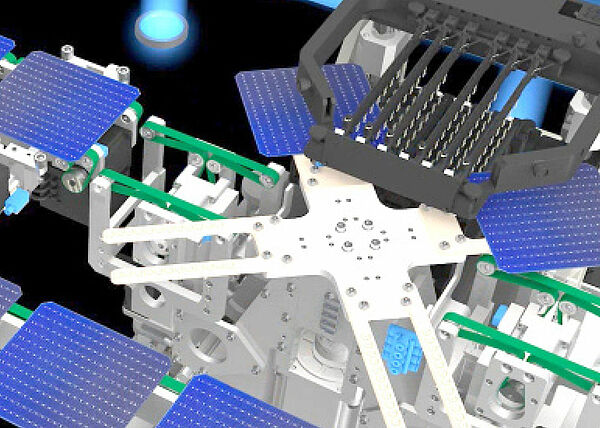

The fastest way to print

The AIRON printer applies metallization paste so quickly that the eye can no longer follow. The line has a throughput of 7,200 cells per hour. It is also the market leader in terms of repeat accuracy of alignment: 12.5 µm with a print quality of 6 sigma. The complete metallization line is optimized in terms of ergonomics and usability and grows with your requirements, such as new cell technologies or line extensions. All future technologies that we develop in the ASYS Group are optionally available in a package with the AIRON. Whether it is the intuitive SIMPLEX operating concept, the smart assistance system PULSE for line monitoring via Smartwatches, or an autonomous material supply using transport robots.

Revolutionary printing technology

We have rethought the AIRON printer from the ground up. The result is the so-called AirSpin process, which makes the wafer float like on air and transports it uniquely fast. You can also expect the following innovations:

- Faster printing, even better quality: The doctor blades are autonomous and therefore travel over the wafer with optimized travel. They thus produce a perfect paste roll.

- Less operating effort for setup: The "Autohead" print head automatically measures the down stop and thus ensures an operator-independent and reproducible print result.

- Protection against microcracks and breakage: The print nest is full-surface and has a soft coating which protects sensitive wafer surfaces.

Tested. Good.

Together with our tester specialists from Botest, calibration and measuring procedures were trimmed for high performance.

- Uniquely fast and gentle: EL test and electrical test in a single contacting process

- From 2 to 6 busbars to multi busbars or busbarless: Specially developed contacting unit ensures unlimited use with minimum shading

- We offer support for the whole machine, also for the IV test unit.

Industry 4.0 meets clever machine design

At AIRON, we have attached great importance to optimum accessibility to all systems. We also use industry 4.0 technology to support the operator.

- Refill paste and change sieve in ergonomic position and in close proximity. Free access to all controls.

- The intuitive SIMPLEX HMI, makes machine operation faster, safer and reduces training effort.

- The operator is informed at every point about the status of the entire line and can control his cluster systems via a central touch screen HMI. Handling systems can also be operated mobile via tablet.

- Loaders and unloaders are AIV (AGV) ready, i.e. they can be connected to autonomous transport robots.

Scalable for the future

Our plants are made in Germany in the best sense of the word. We have customers who have been using our solar machines for more than 10 years. This is only possible because we have always attached importance to scalability and upgradeability. With the AIRON systems we go one step further. All upgrades (except the addition of a fourth pressure step) are merely retrofits in the machines:

- Upgrade to double print

- Upgrade to new cell formats: Wafer size m1-m4 and larger on request

- Upgrade to new cell technologies: PERC, SE, BSF, HJT, Back-Contact-Cells, p-Type, n-Type, Mono, Multi