Automation of Production Processes

The automation of production processes is often divided into different value-added steps. Sometimes at different locations, sometimes only a few meters away, and sometimes globally networked. The intermediate storage or outsourcing of components for further processing characterizes this process. We use our expertise in handling components, trays and pallets on a daily basis to perfect the automation process. For this purpose, we rely on our standard product PARIO, although we can adapt it to your process. The solution for your task is our focus. That is our mission.

Modular and Flexible Interfaces

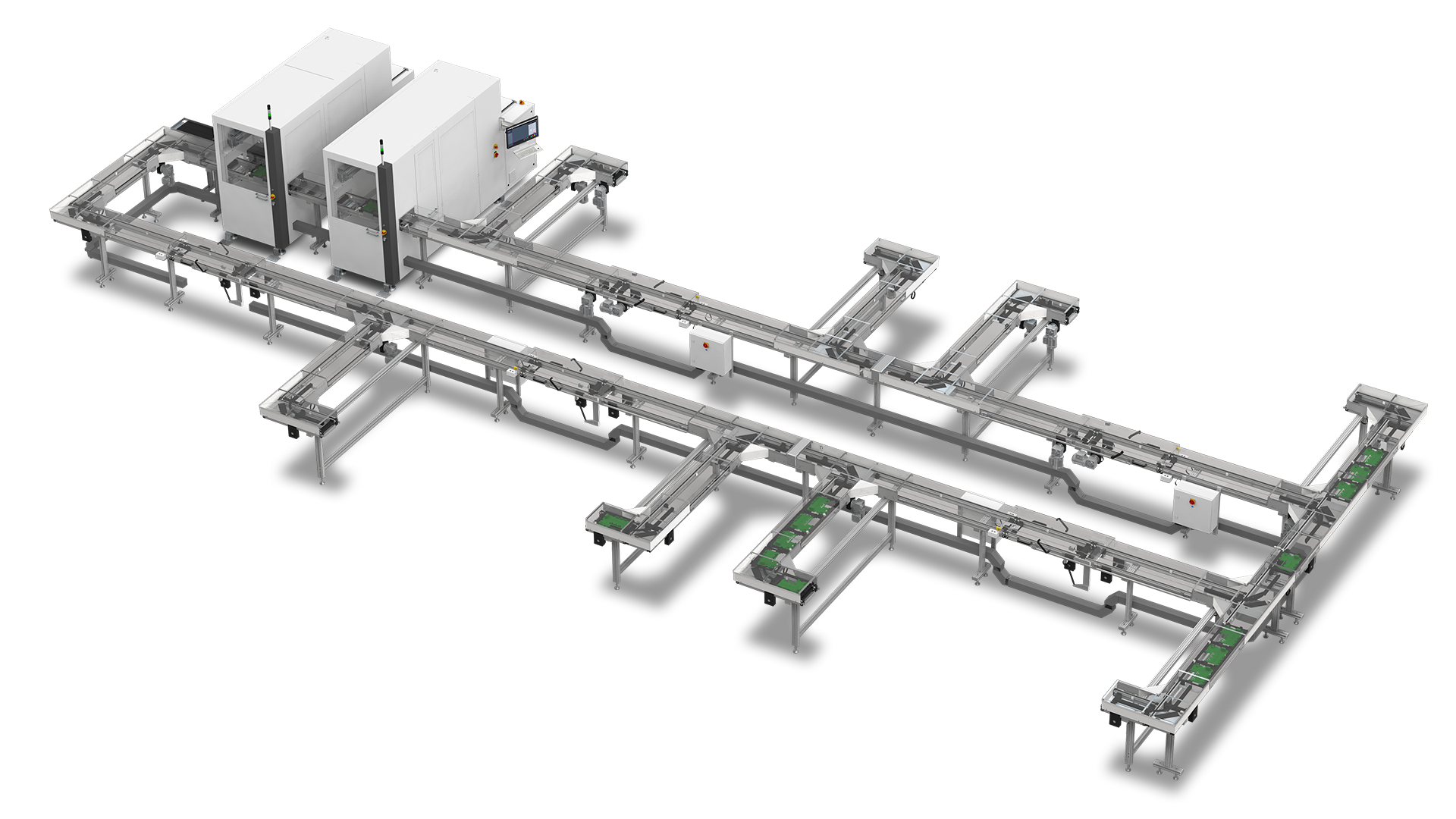

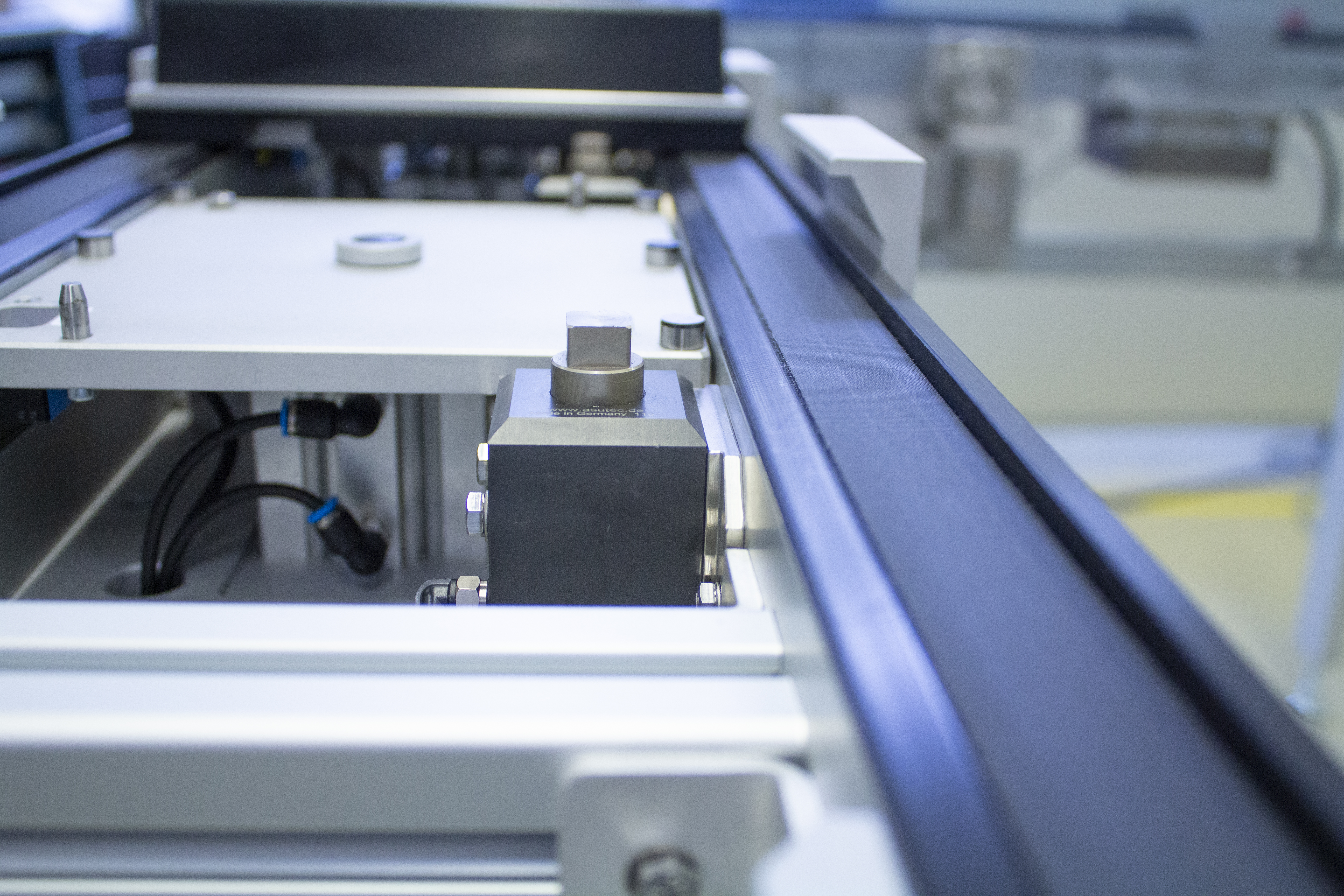

MOTUS transfer and puck systems are the right choice for fully automated assembly systems. Thanks to standardized modules (also in GMP-compliant design), complex requirements can be optimally implemented even in the smallest production areas. The transfer systems can be built with 90° or 180° curves, as a square or with lifts in underfloor technology. The orientation of the product carrier always remains the same. All this with minimum control effort and maximum modularity. Traceability is also guaranteed - all workpiece carriers can be optionally equipped with RFID tags for carrying process data. Due to the modular design, the system can be modified and expanded at any time.

Global Biotechnology Company relies on Fully Automated Palletizing Solutions from ASYS Life Science

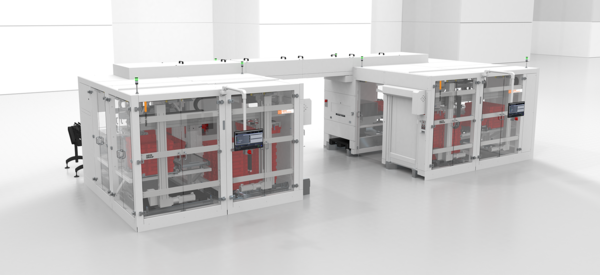

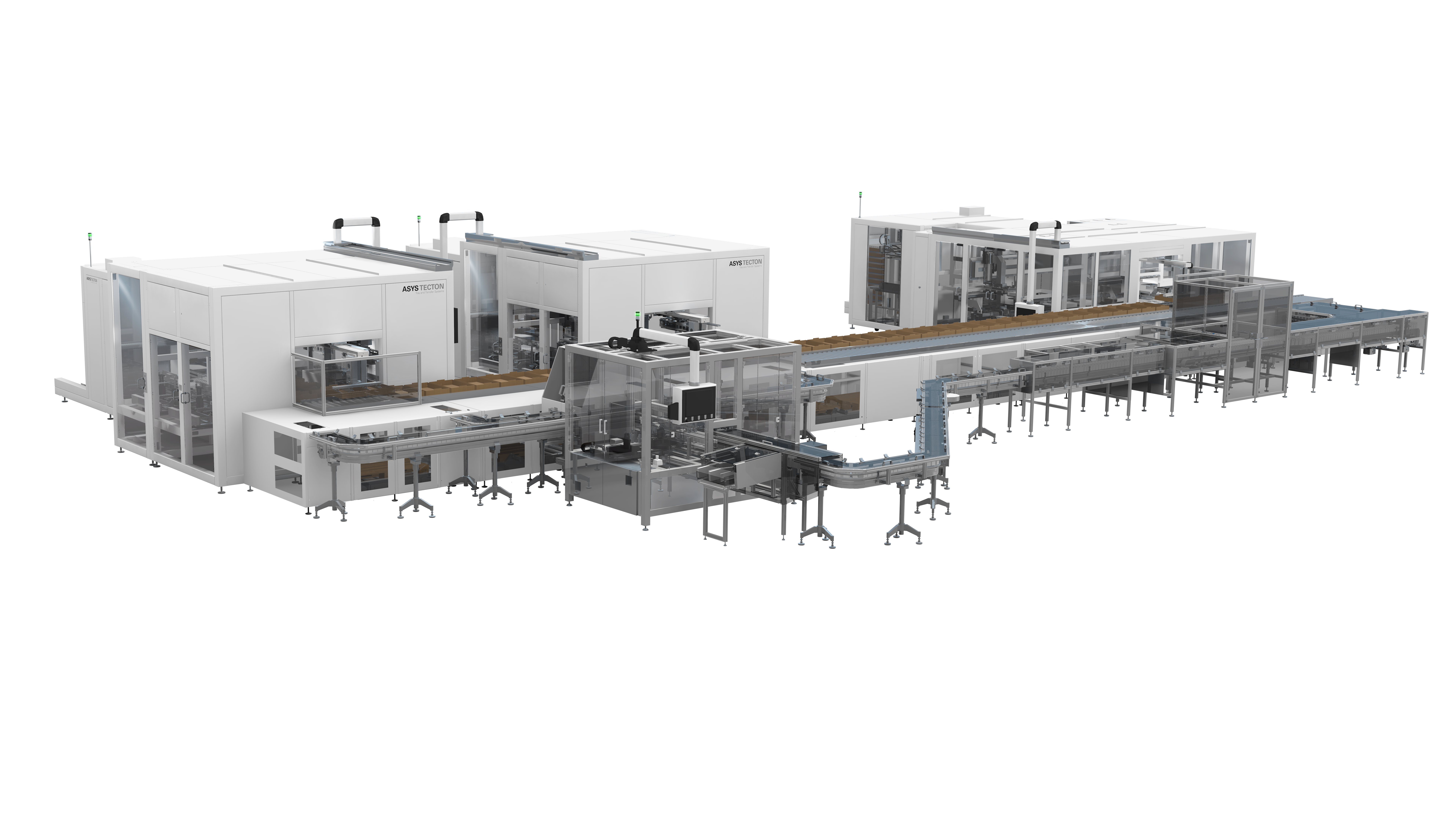

A well-known swiss pharmaceutical manufacturer has set itself the goal of automating manual and repeated activities. In this way, while complying with workplace safety regulations, the goal is to reduce the amount of errors and at the same time increase the output. The focus of the solution is to automate intralogistics processes. In order to automate the previously manual processes, ASYS worked out the perfect solution in intensive cooperation with the customer.

For the fully automated loading and unloading of the vials at the inspection and packaging lines, system solutions from ASYS TECTON are used. Another work step was automated on the same machine base: Depalletizing to separate the 50 and 100 ml vials and subsequent connection to a cartoning machine

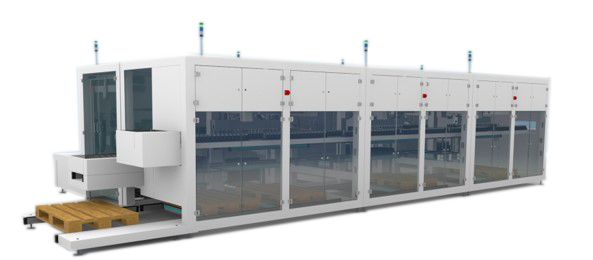

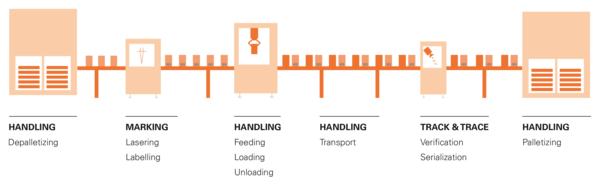

End of line Packaging of Folding Cartons

The ASYS Life Science solutions for packaging are created from equipment of the entire ASYS Group portfolio, such as tray loading and unloading, transfer lines, laser and scanner. If required, machines from third party suppliers can be integrated. The offer is completed by services and documents around qualification.

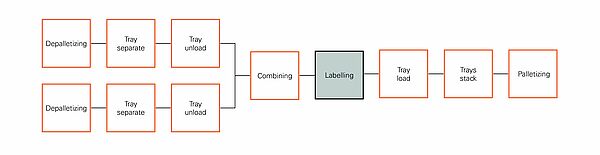

Confectioning of Combination Packages

From the first idea to the finished product. This project shows the competence of ASYS Group in handling, tray unloading and tray loading of reagent cartridges for a large diagnostics producer. Single-variety packs made of cardboard trays are separated, grouped as combination packs, labelled and finally re-palletized. If desired, with a Track&Trace solution from ASYS.

Loading and Unloading of Cartridges with KLT‘s

Loading and unloading from KLT-boxes is a common practice for ASYS. In the subsequent process, different reagents are formed in puck‘s combination stacks. These stacks are fed into a packaging process. We are open to other solution providers and work in close cooperation with them. We also integrate third-party equipment into our processes. Because our focus is ultimately on finding the perfect solution for you. Contact us, we will find a suitable answer to your challenge.