Complete Solutions from one Source

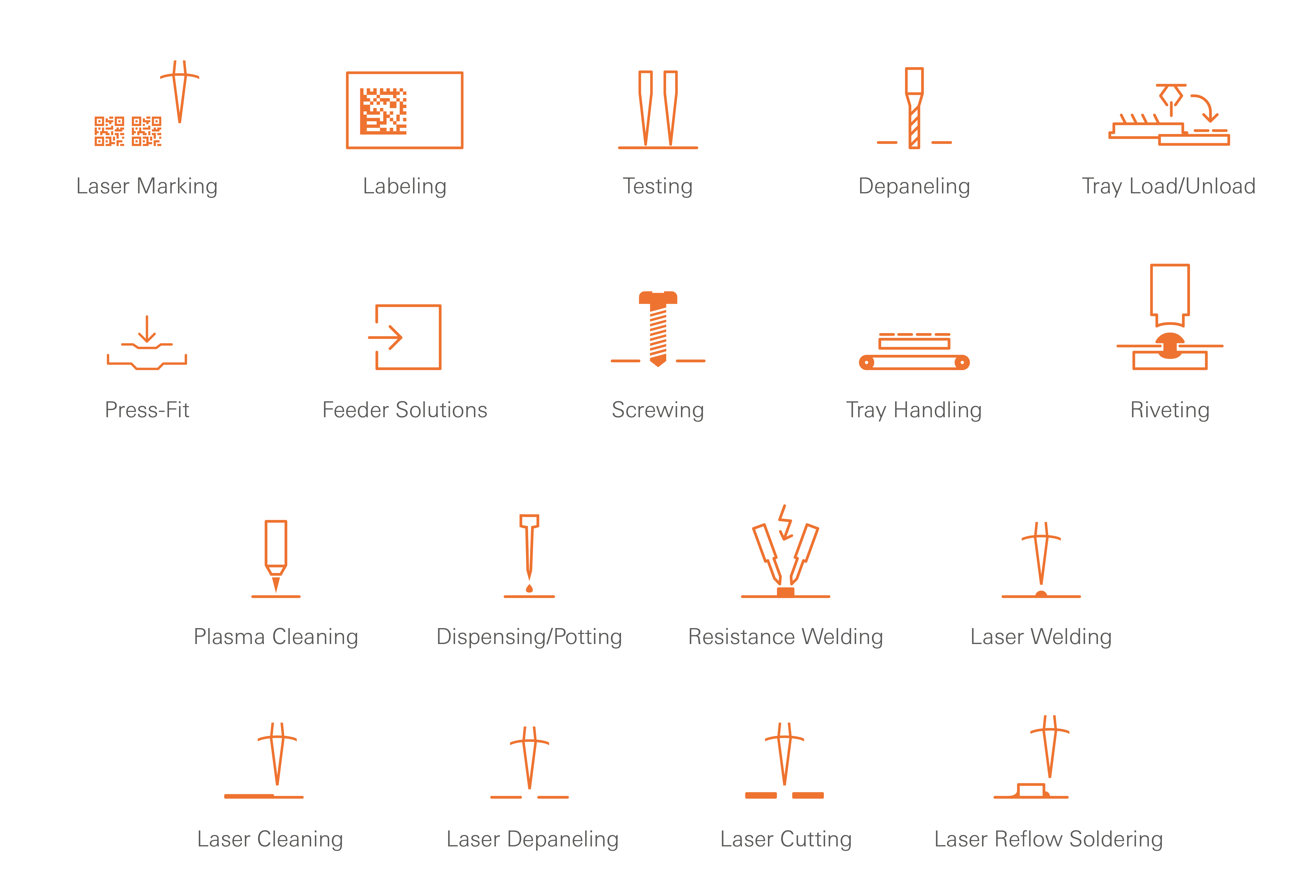

For many years ASYS has been solving assembly tasks for customers in the most diverse industries such as automotive, consumer goods or industrial products. The INVENTUS business unit covers a wide range of automation processes and technologies to design customer-specific solutions. Especially for the Life Science industry, we have developed a new assembly platform and specifically tailored it to requirements of the regulated industry. We use modules from all business areas. This helps us to provide a process-safe and GxP-compliant solution in a short time. We realize complete assembly lines and factory automation from a single source.

Assembly Platform

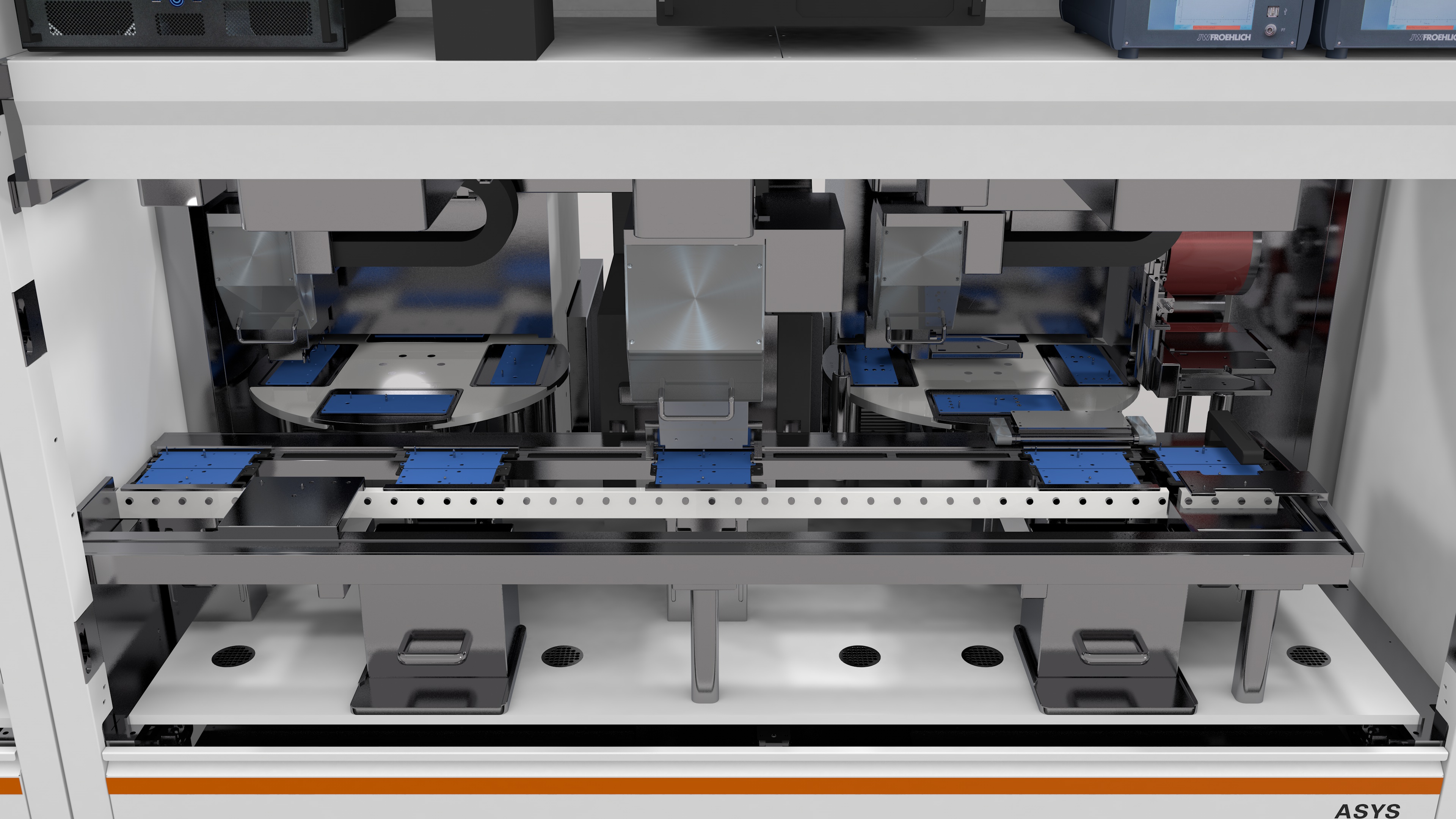

The assembly platform, was developed in close cooperation with customers from the medical technology sector and meets the GxP regulations for production in the environment of 21 CFR Part 820 or ISO 13485. Through the deliberate modular design, the highly flexible platform, allows customized automation solutions, in short project durations. The frames are pre-configured in lengths of 1.5 / 2.0 and 2.5 meters and can be combined to individual cells or lines. The process components (robotics, testers, laser applications, handling, etc.) are mounted on the base plates and aligned with the highest precision. Accuracies of < 10μm @ 6 sigma and more can be achieved.

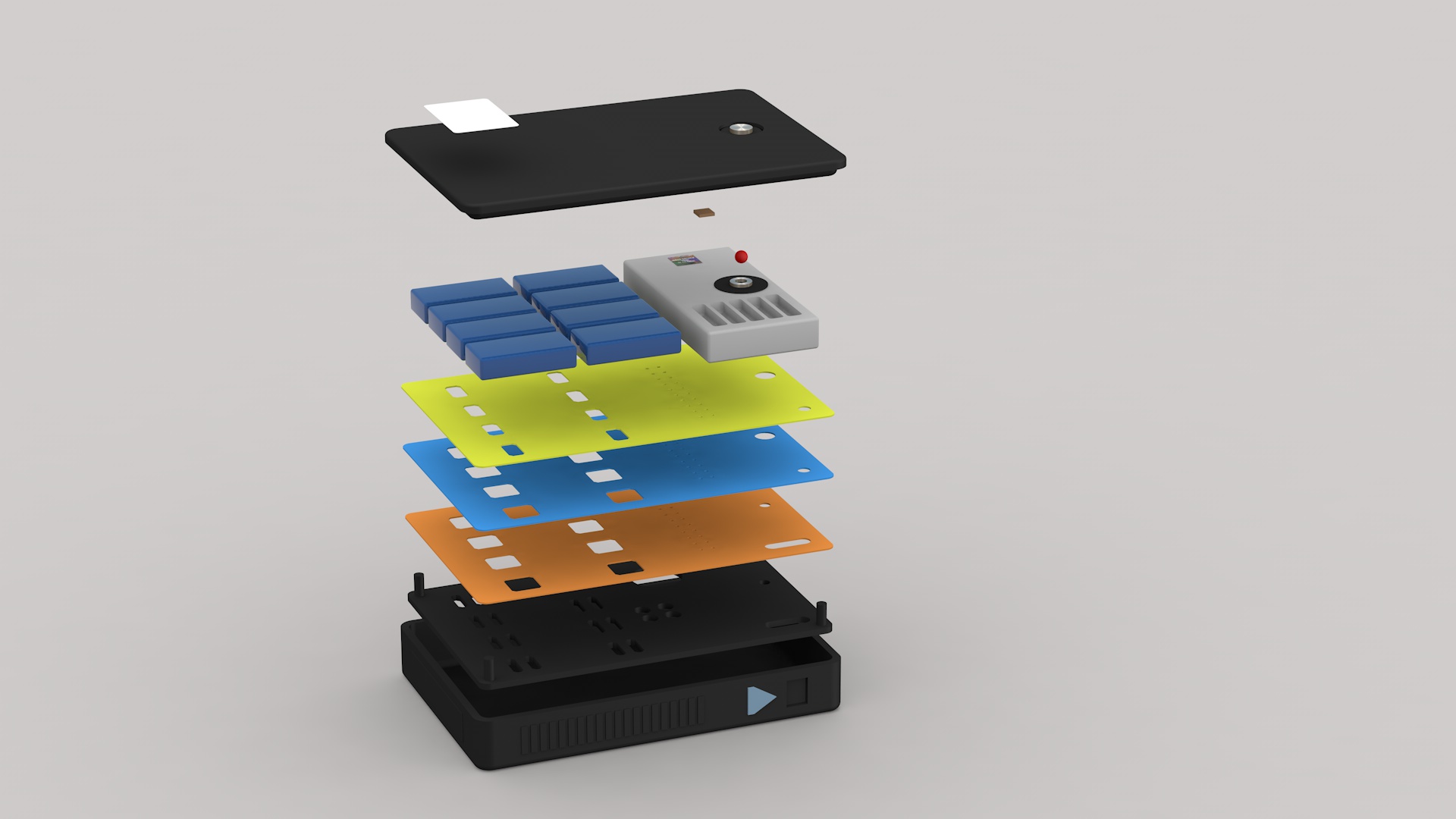

Assembly of the In-Vitro Diagnostic Cartridge

The assembly of hand-sized PCR cartridges for fast diagnostics at the Point-of-Care (POC) has been a trend not only since COVID-19. With the assembly line, realized in this project, approximately 20 individual components are assembled and laser-welded into a functional cartridge in a cycle time of less than 20 seconds. Finally it is packed in an aluminium pouch. Precision, repeatability and traceability in the entire process is a must in this project. With this GxP-compliant Life Science Assembly line, we ensure that the cartridges are produced quickly, safely and economically.

The product is transported on product carriers by belts or magnetic mover systems creating a minimum of particles. Thus we achieve clean room class 5 according to DIN EN ISO 14644-1. The cartridge is picked and placed via a cartesian robot into the rotary table. From there, the cartridge is lifted into the chamber of the mask laser where different layers are laser welded.

Additional requirements for defined, local production conditions with low humidity of < 10% rH or controlled temperature conditions are generated with the optional LAMINO-Flowbox. Complemented by cooling or HEPA filter systems, we ensure that energy is only used where the product requires it. We provide validated environmental conditions at low media costs.

The material selection of the modules, the easy-to-clean design and the good accessibility ensure easy working. Monitoring and setting up from the front, material feeding from the rear. Clean separation of the material flows and of the operating area from the technology, makes it easy for operators and technical personnel.

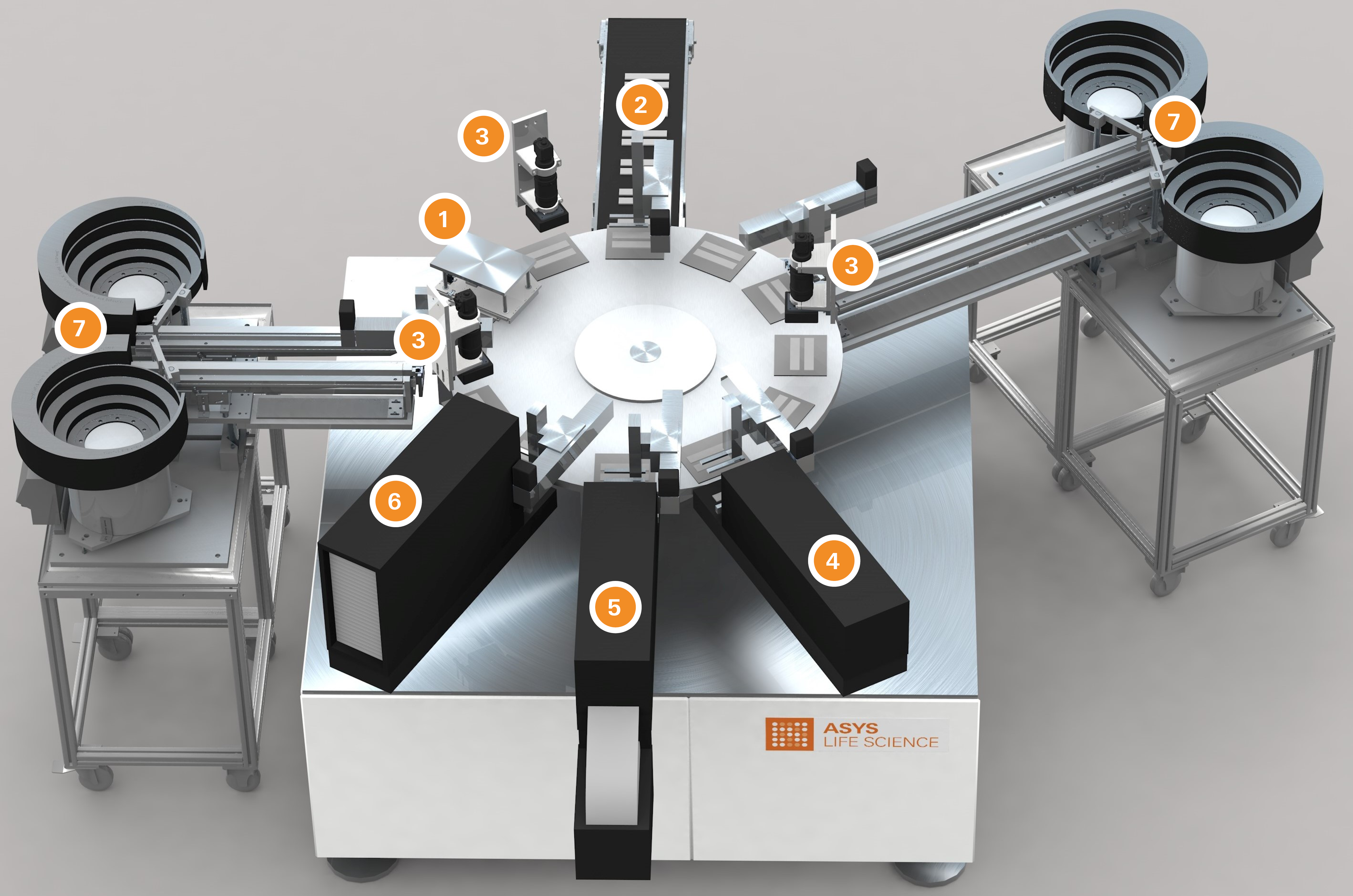

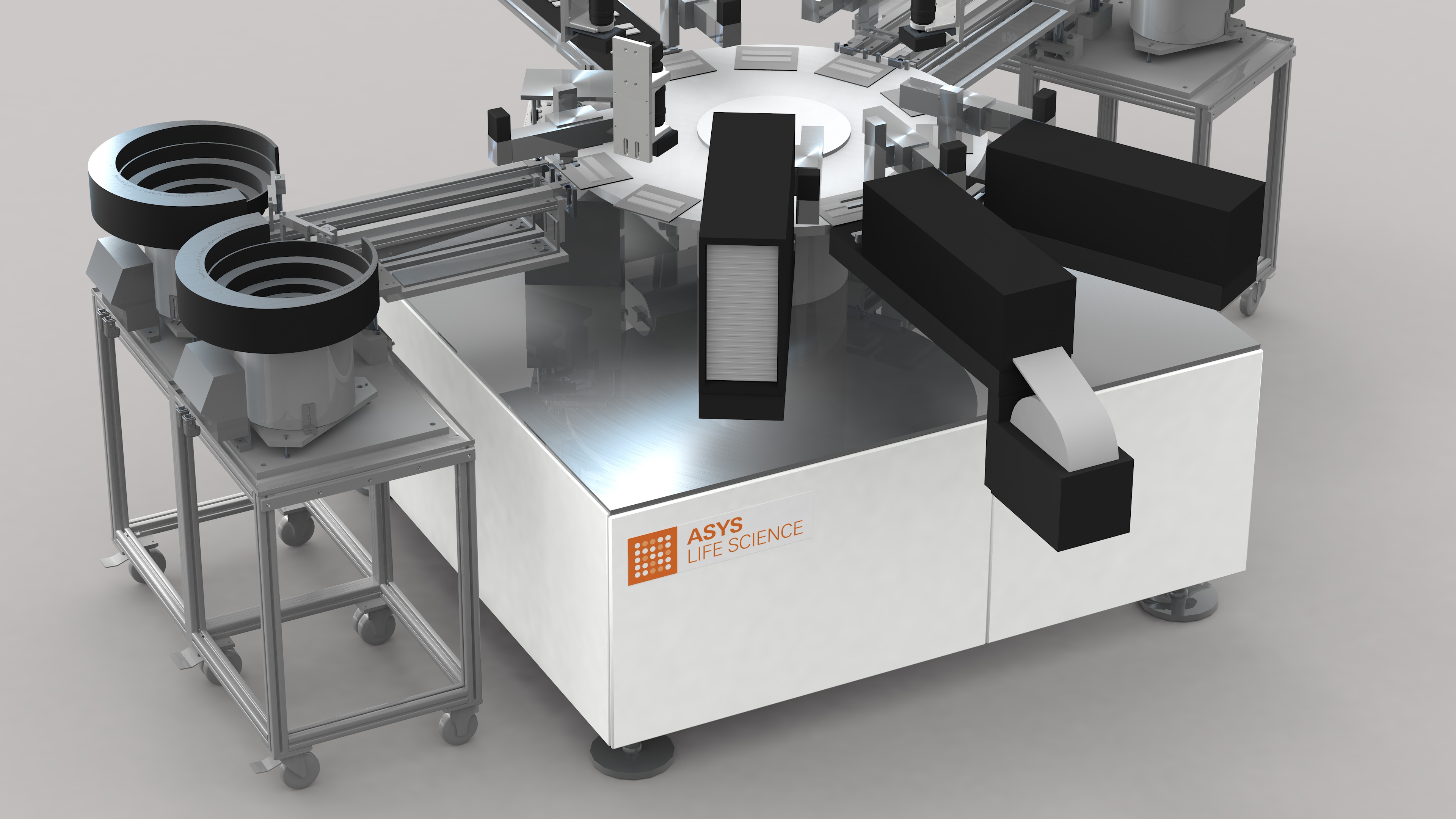

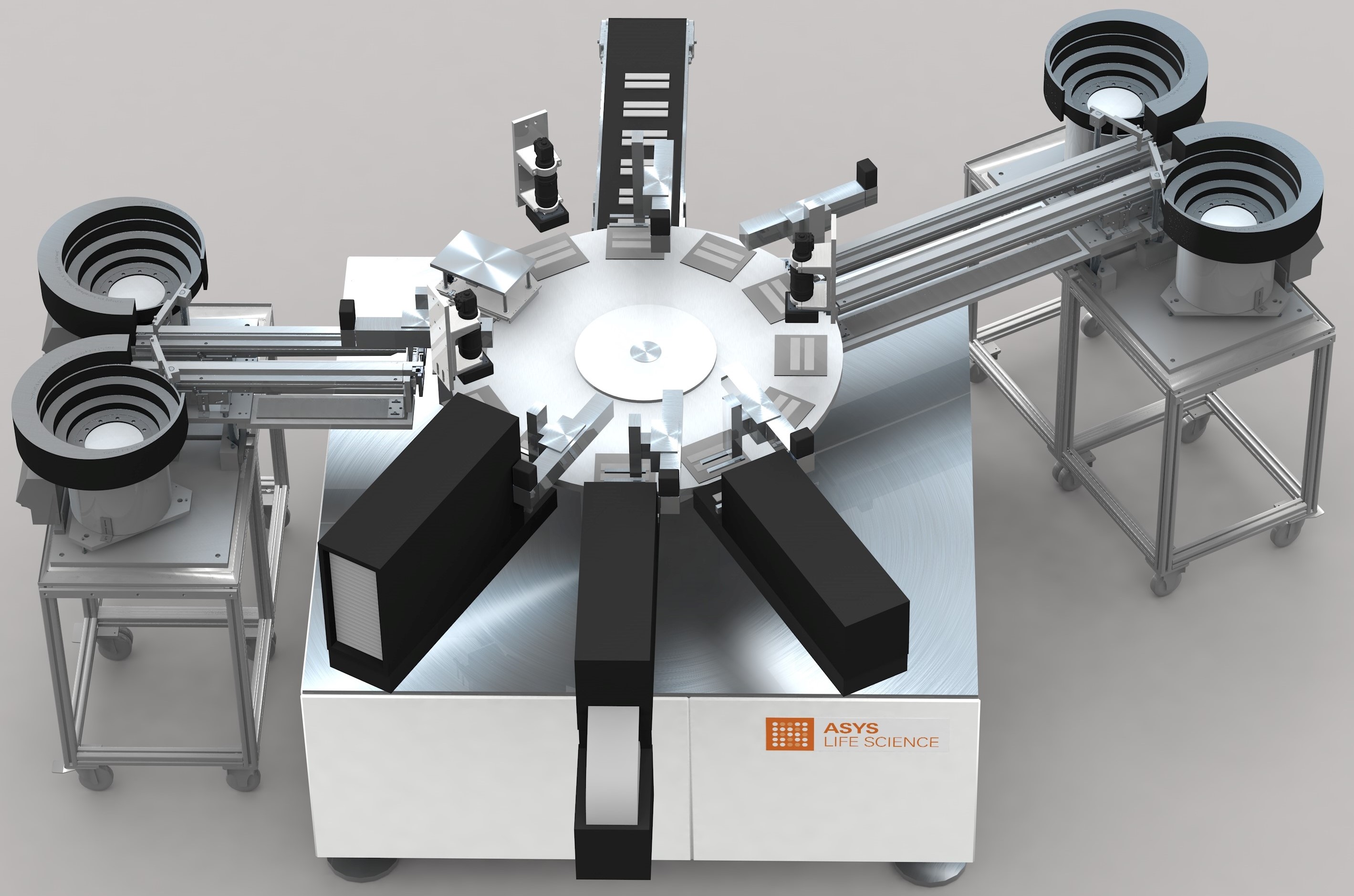

High-Speed Assembly of Rapid Tests

Our high-speed solution allows for the assembly of rapid tests e.g. COVID19, pregnancy, drugs or allergies at output speeds of up to 80 parts/min. These qualitative tests are based on thin-layer chromatography and immune marking of the test strip which is made of porous paper or sintered.

The compact design of our assembly system is based on a rotary table for high precision combined with short cycle times. Gripper and nest design allow fast product changeover according to the Poka Yoke principle and flexible production of product variants with different geometries.

Lateral Flow Device Assembly

The housing components can be fed to the assembly process in bulk via appropriate feeding systems or sorted via trays. The test strips are fed either as roll material or as pre-cut cards in magazines and are cut in the system. The positioning and the joining processes are controlled inline. Each individual assembly step is monitored by a camera control for correct position, shape, and process result, and defective parts are safely separated from the process.

Based on the basic layout, additional process stations can also be integrated at a later stage in order to be prepared for future requirements and product adaptations.

High Speed LFD Assembly

- Flexible rotary table high speed LFD assembly cell

- Output approx. 80 pcs./min. depending on product specifications

- Compact and space saving rotary table system

- Easily adaptable to manufacture different devices

- Flexible set-up of workstations depending on LFD specifications

- Quick and easy change-over with minimal change parts (Poka Yoke)

Housing Infeed Systems

- Feeding systems for housing parts - dual feeder for approx. 80 ppm.

- Space for additional feeders (e.g. caps, desiccants)

- Easy and quick change over

- Variable speed control to adapt to different part requirements

- Low filling level control with pre-warning

- Parts placement with optical part control and bad part reject

- Top mounted Laminar Flow module for cleanliness requirements acc. to DIN EN ISO 14644-1

- Additional requirements for defined production conditions with low humidity of less than 10% rH or controlled temperature conditions are generated with the optional LAMINO-Flowbox

- Cooling or HEPA filter systems ensure that energy is only used where the product needs it

- Validated environmental conditions with low media costs