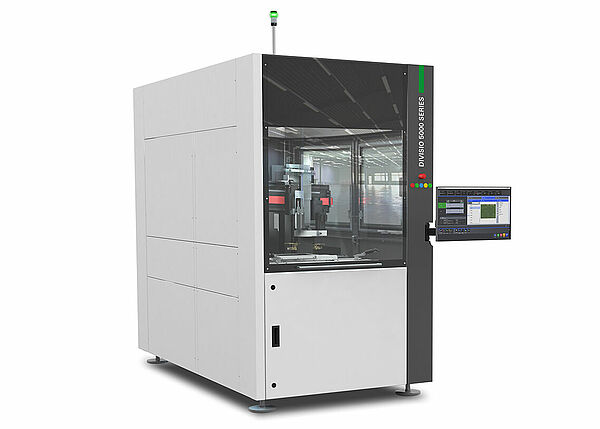

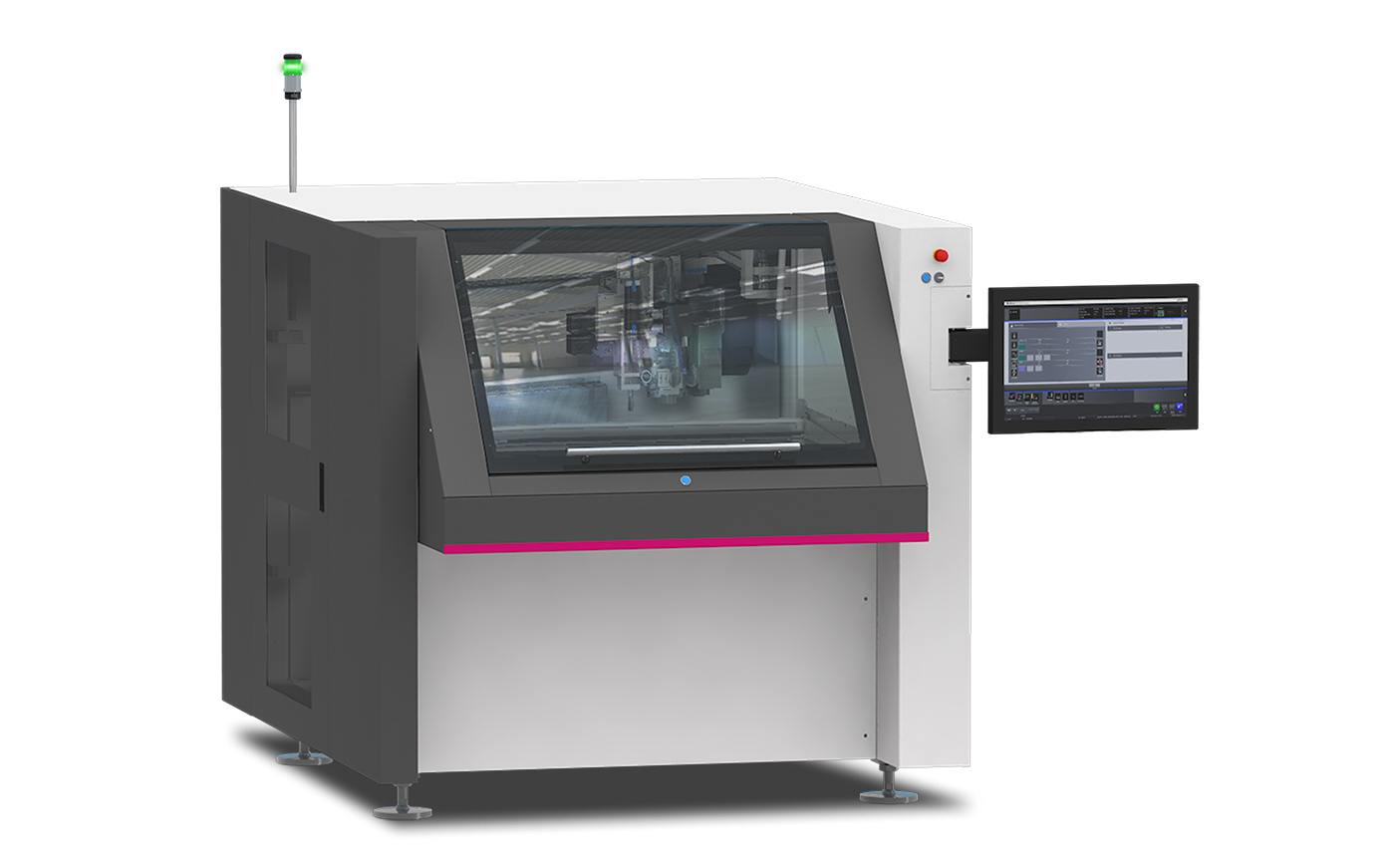

Smart in every detail

The intelligent system interprets its condition itself and controls maintenance and optimization processes as required and with foresight. This allows you to produce up to 150,000 more parts per year. In addition, you increase production time by 4 hours to 20.5 shifts per week.

High process reliability

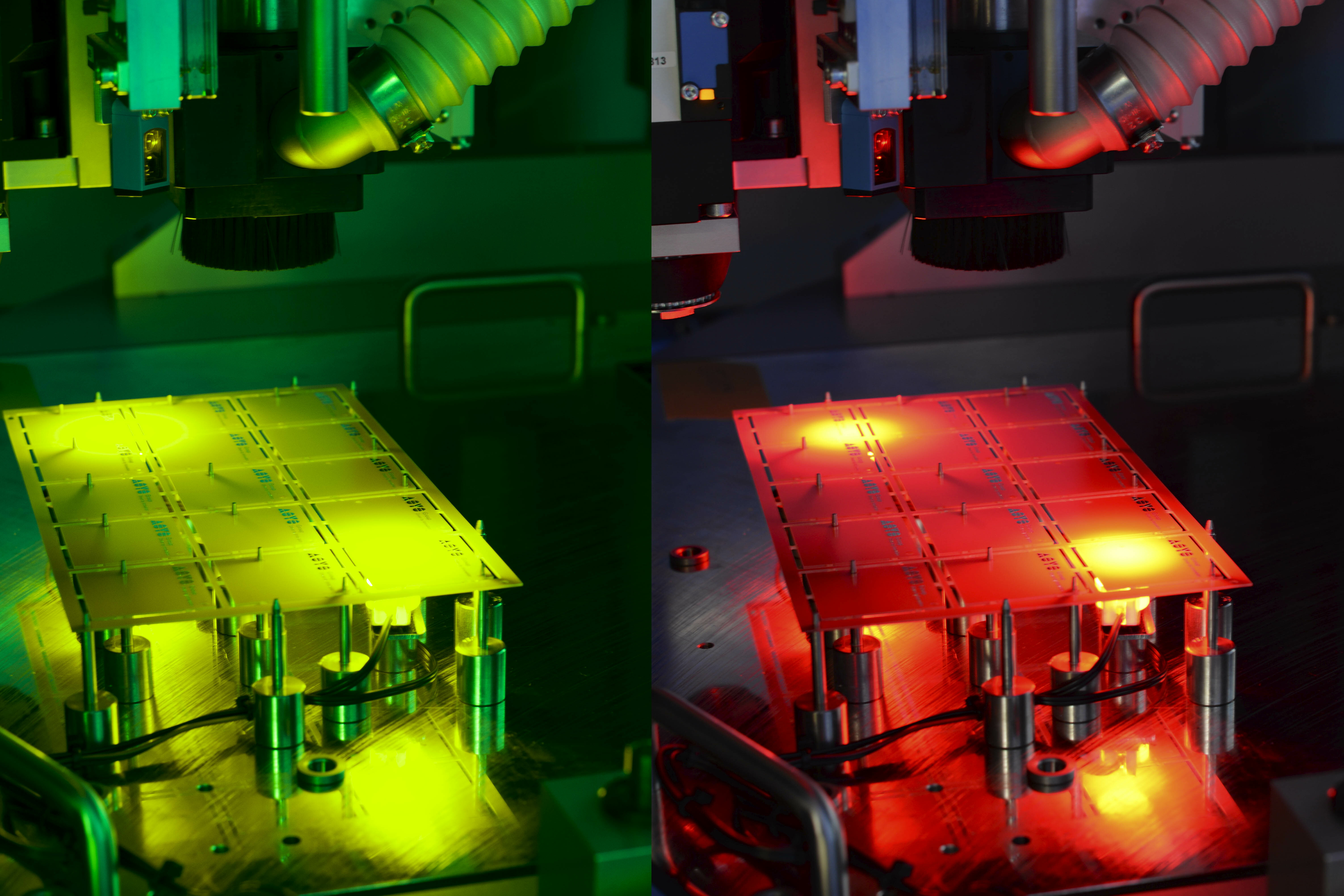

- Parameters are continuously collected and evaluated. This enables the machine to receive real-time information and optimize processes autonomously.

- Always the perfect edge: The system measures the entire cut 100% and adjusts the cutting position depending on the measurement result.

- The force-regulated gripper enables stress-reduced handling. Damage to individual circuits is effectively avoided.

Highly productive manufacturing

- The depanelizer support predictive maintenance and thus achieve maximum availability.

- Based on regular queries and experience, it is determined whether the planned maintenance is actually necessary or can be skipped. The cyclic plan is omitted and the production time is increased.

More operating comfort

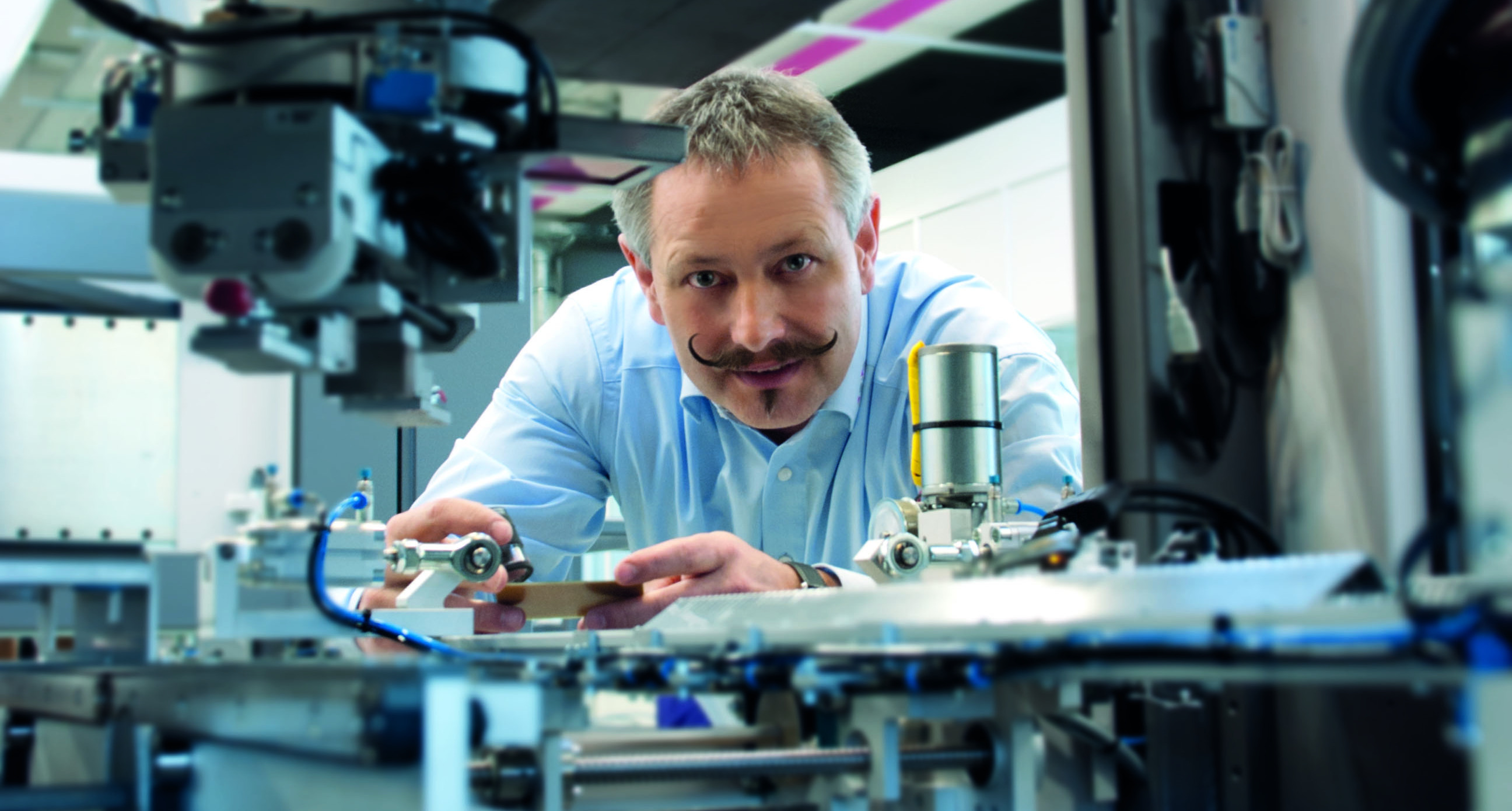

- With the offline workstation, you can program the machine during operation. This significantly reduces downtimes.

- Via smart interfaces, the machine automatically recognizes the correct tool and initiates the product change. This enables faster changeover and reduces operator errors.

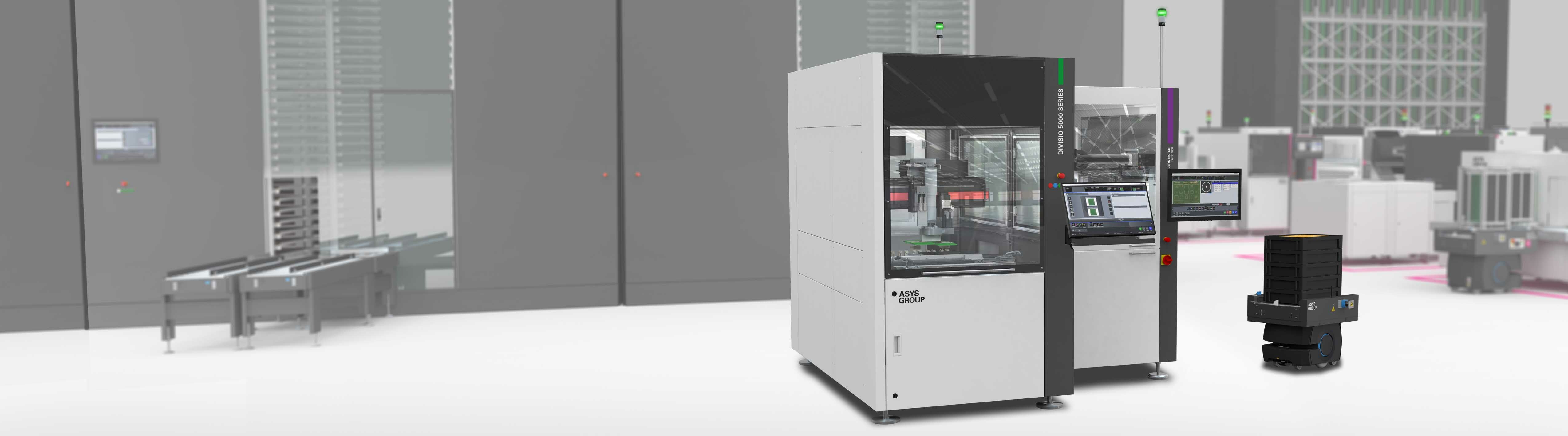

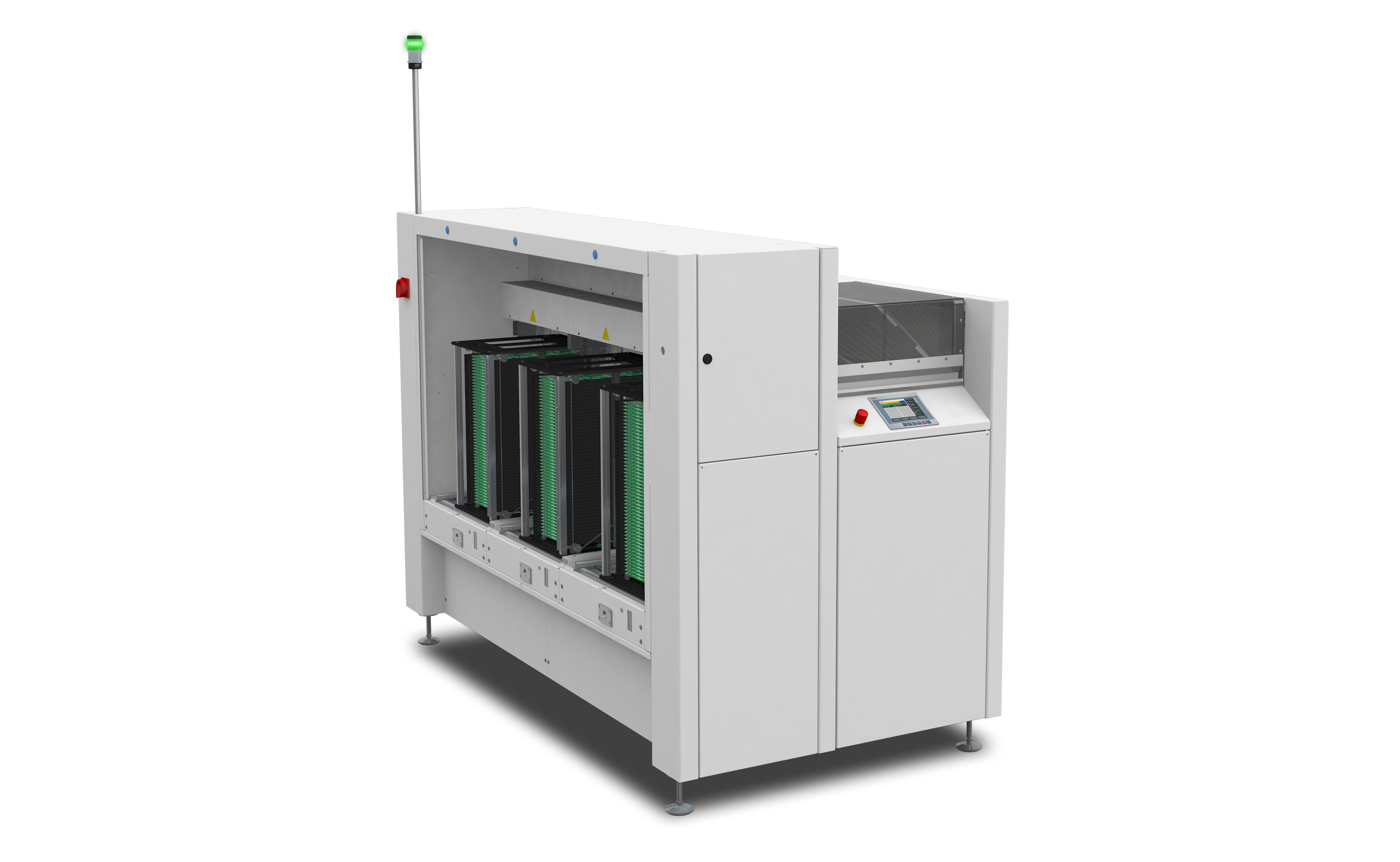

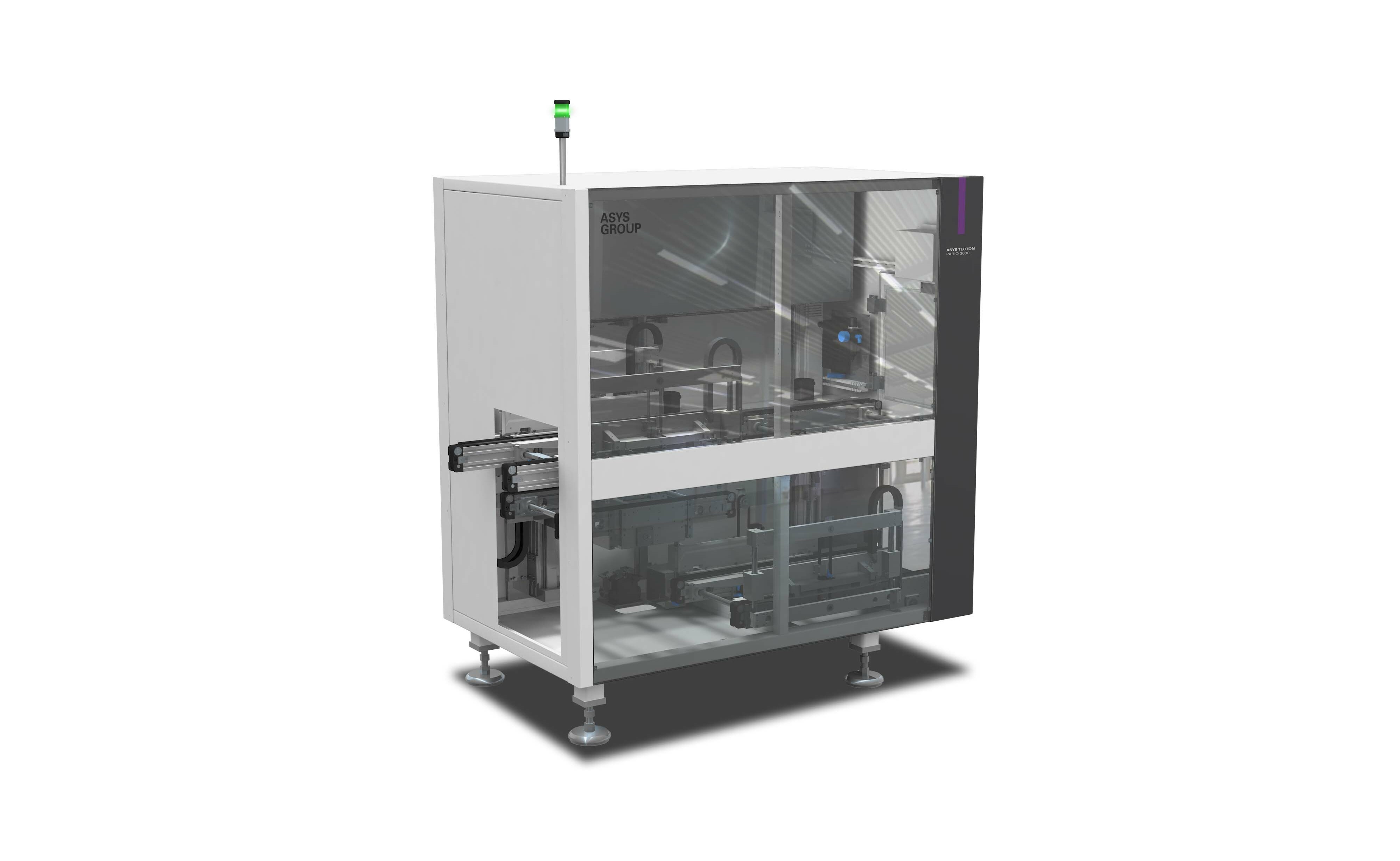

The DIVISIO 5100 can be used both inline and in a production island. In combination with an AES 03 Speed, an INSIGNUM 1000 Scan and a PARIO 800 with lift, the full potential of the depaneling machine is utilized. By automating the loading and unloading with an AIV, 20.5 shifts can be produced without an operator. This increases the production time by 4 hours per week.

- Increased production time

- More throughput

- Reduced consumption of resources