ASYS Storage Solutions for the Smart Factory

Fully automated storage systems such as the Material Warehouse for storage of PCB magazines, KLT boxes and trays as well as the Dry Tower for storage of component reels are available for storage of the various materials. Buffer solutions in the form of M-Stations can be used for intermediate storage or as an interface to manual workstations.

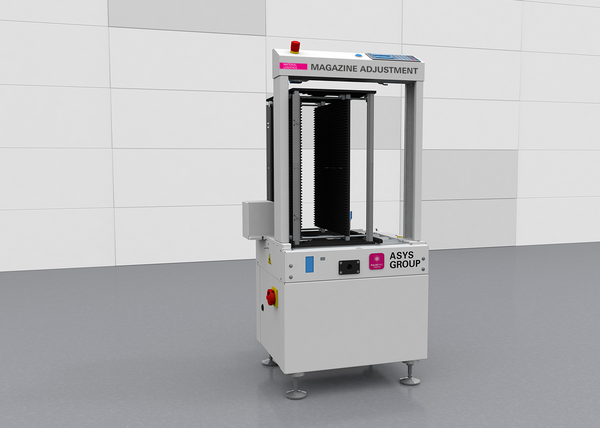

Flexible station for setting the magazine inside width

The MMA is a flexible system for the automatic adjustment of the width of PCB magazines. The system consists of a segment that holds the magazine to be adjusted in order to perform the width adjustment. The transfer and takeover process can be performed manually by an operator, by trolley or by an autonomous mobile robot. During transfer, the magazine is moved against a mechanical stop and gripped automatically. The adjustment mechanism is coupled to the magazine and the track width is adjusted. The magazine‘s movable cheek is first driven all the way out (reference position) and then the magazine width set in advance on the display or transfered by the control system is adjusted.

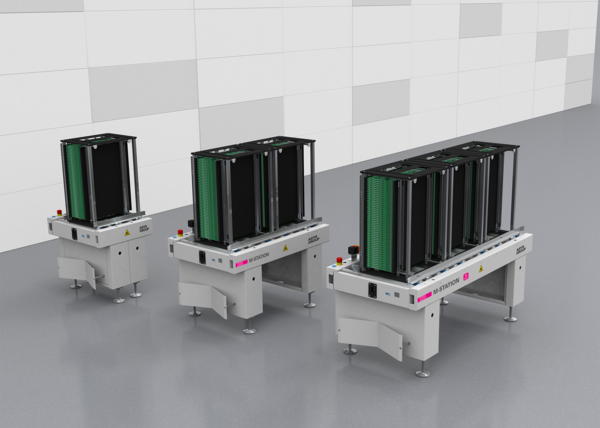

Simple Intermediate Storage thanks to Modular Systems

The M-Station is a modular roller conveyor system to buffer transport goods, like PCB-magazines, Reel-Container, KLT boxes or trays. The M-Station is divided in independent segments, with a number of 1, 2 or 3 segments. The handover and takeover process can be done manually by an operator, by trolley or by autonomous mobile robot. There are several applications available, like a usage as receiving, supply or buffer system. The modular concept allows to extend the system, depending on the number of required positions.

Modular and scalable buffer system for PCB magazines, KLT boxes and tray stacks

The Smart Buffer is a modular and scalable buffer system for PCB magazines, KLT boxes and tray stacks. The buffer consists of 3 to 5 buffer levels as well as upstream and downstream vertical lifts. Due to its modular design, the buffer can be designed with a wide range of buffer capacities. Depending on the available room height, this capacity can be achieved by a configuration in height and length. The internal transfer concept allows direct access to each individual transport unit.

Optimal use of space

Due to the line-like dimensions, the buffer can be placed flexibly and optimized within production environments and fits perfectly between production lines. The ability to place the buffer directly against a wall or back-to-back also allows optimal use of the buffer‘s space. The transfer and takeover process can be done manually by an operator, by trolley or by an autonomous mobile robot. Thus, depending on the degree of automation, the buffer can be adapted to the current production process.

- 3 ... 5 levels

- 3 ... 20 segments per level

- 6 ... 100 buffer locations

- FIFO/LIFO buffer

- ESD compliant

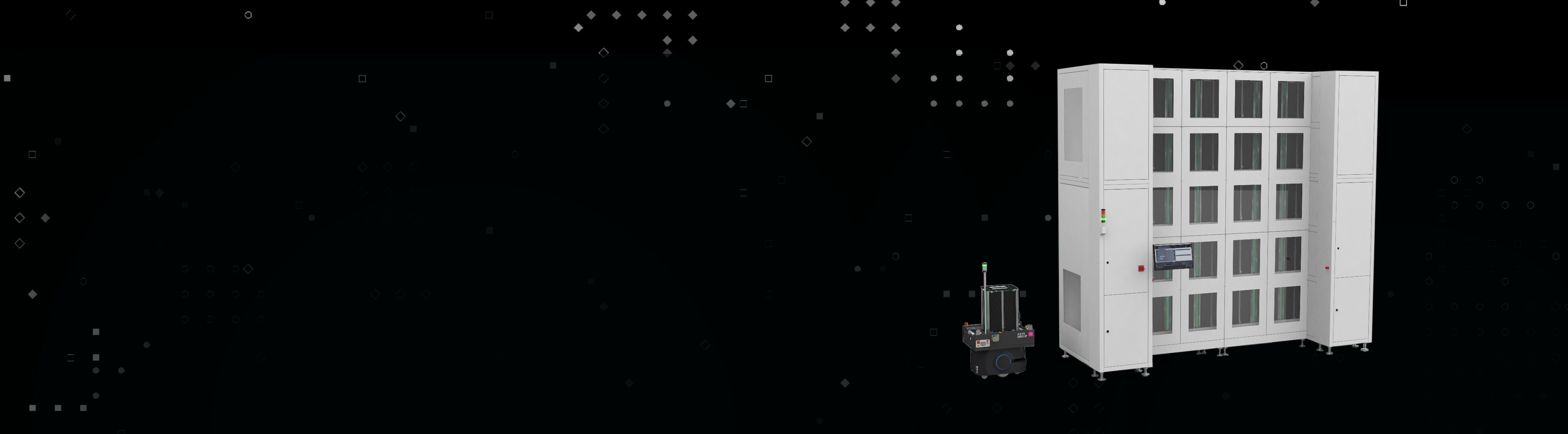

Fully automated, centralized & space-optimized storage for magazines, KLT boxes & trays

In the Material Warehouse, printed circuit board magazines or other materials are automatically stored in KLT boxes in a shelf system according to a chaotic storage concept and can be retrieved at any time. Thanks to clear identification, each magazine is completely traceable. Optionally, the storage conditions can be adapted to the respective requirements of the stored material, e.g. temperature or humidity can be regulated to meet MSD requirements.

Scalable

Like our automation solutions, the Dry Tower and Material Warehouse are scalable. Thus, the material flow can be automated step by step and thus adapted to individual customer requirements. This ensures long-term investment security. Different magazine sizes or other goods carriers for small parts (e.g. trays, KLT boxes) can be stored without any problems, and the storage systems can also be adapted in width with regard to cycle times and shop floor layouts, or can grow with the product.

Fully automated, centralized & space-optimized storage of component reels

The Dry Tower from ASYS / Totech Europe is a fully automated system for the storage of component reels and JEDEC trays and enables autonomous material handling without operator interaction. The system has a proven and advanced drying technology and offers the possibility of controlled storage as well as active re-drying of moisture-sensitive MSL components. Furthermore, due to its consistently modular design, it can be adapted to a wide variety of requirements in terms of size and storage needs. Starting with the storage of the components in the system up to the removal for production, all relevant data of the component processing are stored in a database. This results in a fully automated and reliable storage system that is customized for intelligent SMT electronic manufacturing.

Drawers – Maximum volume consolidation

The Dry Towers consist of up to four cabinets equipped with an optimum number of drawers. The materials placing strategy guarantees volume optimised storage

- Stores up to 4000 reels per m2

- Optimised utilisation of height, depth and width

- Fast access to all components

- Volume optimised storage

- Extendable by combining any number of storage modules

- Drawer layouts can be customized

Storage Cabinets – Unlimited storage in 3 dimensions

Each cabinet comes with a maximum surface area of 2.2 m² and – depending on its height and the size of stored packages – accommodates up to 125 drawers with a total utilizable storage area of 210 m². For each cabinet, this means 5,250 reels* if stored individually or 10,375 reels* in the case of twin-storage. For single-storage, the drawers have been equipped with anti-slip mats; for twin-storage they provide locating pins.

*Refers to reels of 7“ in diameter and maximum 15mm height

- Manual removal possible, if necessary

- Reliable, highly advanced technology

- Maximum volume consolidation

- Quick access

5-axis Gripper System – Gentle component transportation

The gripper systems are driven by low-noise and low-maintenance servomotors and move simultaneously within a 5-axis system. Vacuum grippers transport component packages like reels, trays or boxes quickly and safely. Maximum loads of up to 3 kilos are possible.

- Short access time

- Safe and gentle transportation

- Reels, trays and other unopened packages can be moved

Conveyor Technology – Individual and customized solutions

The Dry Tower can be equipped with custom-engineered conveyor technology for batch processing of reels and boxes, catering for decentralised loading/unloading as well as line supply. Our system allows for maximum flexibility in your component logistics, as each batch is automatically transferred by roller and belt conveyors, lifts or autonomous transport system to the best available position.

- Minimum personnel time

- Just-in-time line processing

- Decoupling of loading and retrieval processes

Climate Control – Perfect storage conditions for electronic components

Our U-7000 series drying unit guarantees controlled humidity values less than 5% RH. When moisture-sensitive components are stored in the unit, the processing time sequence as well as the humidity absorption is automatically stopped. Any possible oxidation of sensitive metal surfaces of components is prevented by electrolyte deprivation. Combined with a 40 °C or 60 °C heater, the entire storage system, or just a separate area within it, can be tempered. Any expired MSL components can be gently re-dried at the right temperature.

- Permanent re-drying of components according to JEDEC standard

- Fast re-drying thanks to minimum relative humidity

- Optional heating (up to 60˚C) accelerates drying process

- Oxidation processes are prevented

Software – Perfect documentation

The standard interface allows for the integration of the Dry Tower into your existing MES system. Important storage data and parameters such as humidity, temperature and operator intervention are documented. Our integrated commissioning function enables efficient retrieval in the desired sequence and with regard to FIFO.

- Reliable monitoring & documentation of moisture sensitivity levels as well as drying, stopping and processing times according to JEDEC standards

- Automatic commissioning function

- Standard interface for integration into existing systems

- Seamless logging along entire logistics chain

- Unrivalled versatility thanks to freely configurable storage strategies

Dry Tower SMD storage systems in action

Some well-known electronics companies are already using the Dry Tower SMD storage system to improve material logistics and achieve their Smart Factory Industry 4.0 goals.

Approx. 90% of all components required in SMD production are stored in the Dry Tower. Since the use of the Dry Tower, the storage and retrieval processes have been drastically reduced and search and waiting times minimized. The high growth could not only be handled without additional manpower, but the employees can also focus more on the value-adding activities.

In the current project, all opened reels and the most frequently required full reels are stored in the Dry Tower, approx. 80% of the material requirements of the production are traded via the Dry Tower in this way. After finishing, the reels are stacked on a trolley and then fed to the Dry Tower. The booking and storage process is fully automatic from this point on. On the retrieval side, a completely new solution - unique on the market - has been developed: The reels are stacked in a box standing on edge. This ensures that each reel is easily accessible for the operator when a batch is retrieved.

Storage Systems for Consumables

We offer an intelligent and air-conditioned material storage system for consumables in the production. The controlled dispensing of solder paste and other consumables is based on the FIFO principle.

Air-Conditioned Storage and Controlled Distribution of Consumables

Thanks to its modular design, the EKRA S10 select material storage system offers flexible storage options. It can be integrated into production in a space-saving manner and eliminates long walking distances to an outsourced material storage system. The S10 select is a storage system for solder paste and other consumables based on the FIFO principle. Password-secured and equipped with a hand scanner or an optional label printer, it ensures controlled material output and supports quality assurance processes in the company. In order to meet product-specific requirements, it is possible to flexibly set temperatures between 4°C and 25°C. The material is dispensed in a resource-saving manner The expiration date can be defined for the respective material in order to control timely consumption. The S10 select can be connected to our PULSE system and can thus transmit temperature warnings to the smart watch. A special storage system with chute can automatically transfer materials to an AIV.

Store Stencils and Set Them Up

Our S10 portfolio offers not only consumables but also storage and set-up systems. The S10 mobile is a set-up and storage system directly on the line. Stencils, pastes or squeegees can be stored, prepared or cleaned here. The S10 modular is a storage system for stencils and, thanks to its modularity, can be extended to larger cabinet units.

Storage and Drying of Moisture-Sensitive Components

The CONSIDUS dry storage systems from ASYS Prozess- und Reinraumtechnik ensure optimum dry storage conditions. A relative humidity of less than 3% can be achieved in less than one minute. This can be done by two methods: Adsorption technology (circulating air principle) or nitrogen flushing (displacement principle). The cabinets can be adapted to the specific requirements of the stored goods. In addition, a tempering furnace can be installed in a closed cabinet segment. The entire cabinet volume can be heated to 40° for active component drying.